I found the flat belts in Mc Master but there was 3 kinds of leather belts that popped up. Which belt is suggested for a 9A. Also should i get the staples or the hammer style clips. Id like to use which ever clip is easiest to work with but without buying elaborate tools to staple one belt together. Thank you!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help on replacing the belt

- Thread starter Brento

- Start date

- Joined

- Jan 2, 2014

- Messages

- 8,854

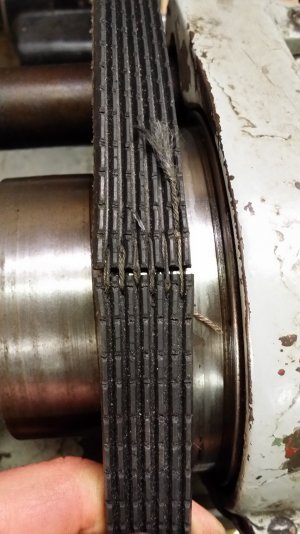

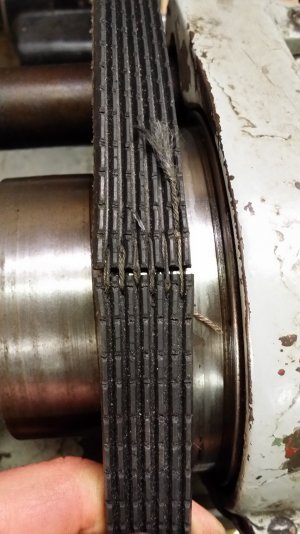

On my Southbend 9" I re-use old automotive serpentine belts. When they start squealing or cracking on my truck they get replaced with new and the old ones become shop stock. I usually have 1-2 old belts ahead of what I need.

Initially I tried a long diagonal scarf joint (for increased surface area) and cyanoacrylate adhesive. But, as usual, I found that it works sooo much better on skin than on any project I need to repair.

Now I cut them off square and stitch the ends together. I will pre-drill the stitch holes on the drill press to make it easy. I usually use the tough cord that came with this kit:

https://www.leevalley.com/en-ca/sho...50700-speedy-stitcher-sewing-kit?item=97K1050

But any strong thin cord should work.

I first cut the belts as long as useful for the lathe, then even if/when the cords pulls thru the cut end of the belt, I can re-cut, drill and stitch and get another use, due to the adjustment available in the lathe pulleys.

I run them flat side out, and stitch such that the "thread" is in the belt grooves and therefore protected from wear.

Also, I always release the tension on the belt when the lathe is not being used.

Pictures below. The belts edges look mis-aligned below, but it's only since the belt is loose. When tight it tracks well.

-brino

Initially I tried a long diagonal scarf joint (for increased surface area) and cyanoacrylate adhesive. But, as usual, I found that it works sooo much better on skin than on any project I need to repair.

Now I cut them off square and stitch the ends together. I will pre-drill the stitch holes on the drill press to make it easy. I usually use the tough cord that came with this kit:

https://www.leevalley.com/en-ca/sho...50700-speedy-stitcher-sewing-kit?item=97K1050

But any strong thin cord should work.

I first cut the belts as long as useful for the lathe, then even if/when the cords pulls thru the cut end of the belt, I can re-cut, drill and stitch and get another use, due to the adjustment available in the lathe pulleys.

I run them flat side out, and stitch such that the "thread" is in the belt grooves and therefore protected from wear.

Also, I always release the tension on the belt when the lathe is not being used.

Pictures below. The belts edges look mis-aligned below, but it's only since the belt is loose. When tight it tracks well.

-brino

- Joined

- Jun 7, 2013

- Messages

- 10,122

Hammer on belt lace (Alligator Lace) is to be avoided at all costs; it is big, clunky and crude, very noisy going over pulleys. The old standard clip on lace, made by Clipper is the best, but requires a tool to apply it, these can be found on e bay and other sources, the clips come in many sizes, and the smallest require a differently sized tool than the larger ones. Soft annealed brass wire can also be used to lace belts in the manner shown above by brino Endless flat belts can also be used, but require disassembly of parts of the lathe, such as the spindle and countershaft.

- Joined

- Oct 13, 2014

- Messages

- 7,007

I use the nylon cored leather belting from McMaster Carr. It doesn't stretch out like the solid leather does. Have a hammer-on alligator clip on one lathe (I don't mind the sound) and I laced up the other belt, similar to Brino's method.

- Joined

- May 4, 2019

- Messages

- 792

I had a belt that was slit from conveyor belting. It was joined with Clipper lacing. No stretch. The clipper lacings eventually pulled out. I couldn't find anyone locally had a clipper lacer so I bought a synthetic belt on eBay. Since then I acquired a Clipper lacer.