- Joined

- Apr 29, 2019

- Messages

- 2,063

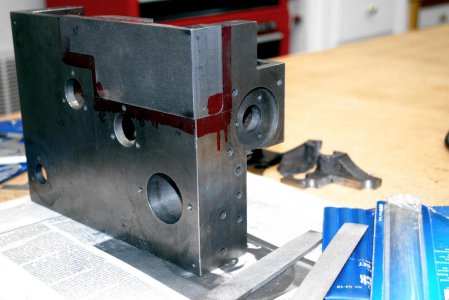

Those voids look like it was just lack of filler, Don't be afraid to build the filler up well above the finished height, You will machine off the excess anyhow but you will be less likely to have low spots.

If those were voids that only showed up after machining, then you may have been going to fast and trapped flux or air in the joint or there could have been porosity or inclusions in the cast iron that bubbled out into to the filler metal.

If those were voids that only showed up after machining, then you may have been going to fast and trapped flux or air in the joint or there could have been porosity or inclusions in the cast iron that bubbled out into to the filler metal.