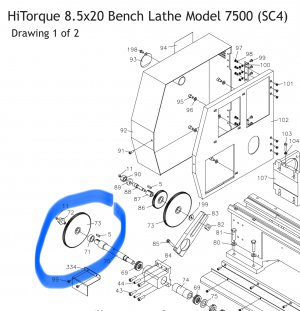

Doing the Claugh42 ELS upgrade on my lathe and would really like to get this gear out of the way. I have a timing pulley which will mount to the 16mm shaft directly below the spindle. The encoder mounts to the right. I can get a much cleaner install if the gear shown here is gone. Have looked in the parts diagram in the manual and the shaft goes through the plate inside the lathe, but it seems there should be a simple way to remove the gear and leave the shaft in place.