Those numbers are unique to each manufacturer, so you will need check the manufacturer’s website to see what each mean. In the case of the inserts you referenced, the F1 indicates that’s a finishing grade, so will work for light cuts. If you needed to take finer cuts than the minimum depth of cut of 0.01” shown on the back, you might want the FF1 design. The Kennametal equivalent to the Seco F1 is LF, so you can’t directly interchange without the manufacturers charts like you can with the insert size numbers. MSC has a chart that shows how the different chip breaker styles compare.Thanks. I have a similar chart and David's book. The devil is in the details. I don't know what coating or edge treatment to look for and I don't know how to tell by the insert numbers.

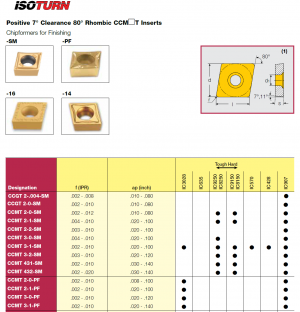

Chipbreaker Cross Reference & ANSI Insert Nomenclature Technical Information | MSC Industrial Supply Co.

Look here for a chart with technical information ANSI insert nomenclature and the chipbreakers carried by MSC Industrial Supply Co.