- Joined

- Dec 17, 2020

- Messages

- 56

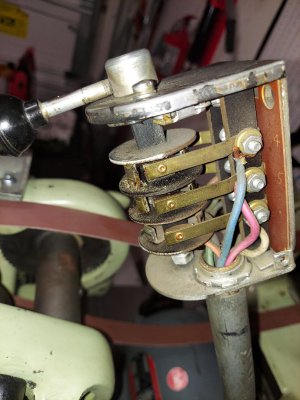

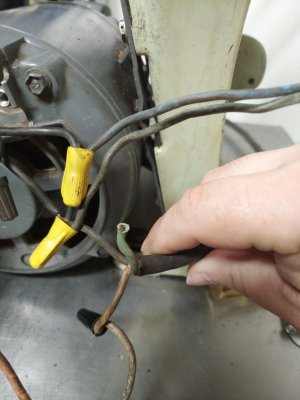

Ok so I need a little help the South bend 9A that followed me home was overhauled not painted (although I should have but no space, I installed a South bend switch and got away from the floppy pole with a switch. I found 1 black wire taped off and the Green wire (Ground or Neutral) coming from the outlet wire, there are 6 black wires coming out of the motor. Also there are multiple wires in the wire nuts some have 3. I just want it wired properly. I wired the barrel switch as it came apart same with outlet plug, I replaced both the 6 conductor wire and the wire to the wall. I used very heavy gauge wire for both (what I could get). I will try to include pics and sorry for the terminology I am no electrician. How is this suppose to be wired correctly? It did run before.

Attachments

-

SB 9A switch wire 1.jpg108.8 KB · Views: 17

SB 9A switch wire 1.jpg108.8 KB · Views: 17 -

SB 9A switch wire pic 2.jpg119.8 KB · Views: 15

SB 9A switch wire pic 2.jpg119.8 KB · Views: 15 -

thumbnail (1).jpg142.9 KB · Views: 14

thumbnail (1).jpg142.9 KB · Views: 14 -

thumbnail (2).jpg134.6 KB · Views: 15

thumbnail (2).jpg134.6 KB · Views: 15 -

thumbnail (3).jpg134.6 KB · Views: 13

thumbnail (3).jpg134.6 KB · Views: 13 -

thumbnail (4).jpg114.5 KB · Views: 13

thumbnail (4).jpg114.5 KB · Views: 13 -

thumbnail (5).jpg104.8 KB · Views: 21

thumbnail (5).jpg104.8 KB · Views: 21 -

thumbnail (7).jpg99.2 KB · Views: 22

thumbnail (7).jpg99.2 KB · Views: 22 -

thumbnail.jpg143.7 KB · Views: 22

thumbnail.jpg143.7 KB · Views: 22