Note to self, always take pictures, and then take better pictures.

The FWD/OFF/REV switch on my HF 33686 Milling Machine stopped working most of the time, intermittently worked.

So I took it apart, I did find two sets of contacts that were burned and pitted, but were far from the worst I have seen.

I cleaned them up. Now that I have torn it all apart, I'm questioning whether the switch even had a problem, because after several

assemble and check of rotation, cams and switch pointer, all of the sudden I turned the switch and the shaft dd not turn. Then the screw

to tighten the clamp around the shaft becomes obvious.

This leads me to believe that the original problem was the knob rotating around the six sided shaft feeling like a detent, and not switch contacts.

I run the machine on 120Vac.

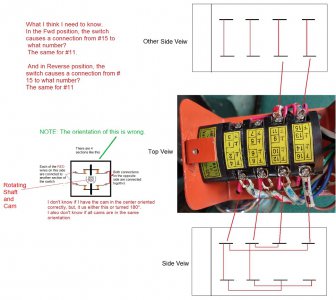

Now I'm trying to reassemble the 4 section switch with 12 springs and 16 separate contacts that need to be put into place.

And then the cams also need to be installed properly, however, I think they are all in the same orientation, so that may be easy.

AC---Hot and Neutral come in on two connections and on the opposite side are 4 connections that go to the motor.

I can probably do this* if someone can give me a drawing with 4 wires from a motor wired for 120Vac showing how

forward and reverse are implemented. Even if it uses 2-SPDT switches to show the wiring.

Can someone make or find a drawing of such.

**Assumes parts don't go flying more times than I can find them. Already lost a spring but the junk draw had one.

I've searced the carpet for a part 5 times already.

The FWD/OFF/REV switch on my HF 33686 Milling Machine stopped working most of the time, intermittently worked.

So I took it apart, I did find two sets of contacts that were burned and pitted, but were far from the worst I have seen.

I cleaned them up. Now that I have torn it all apart, I'm questioning whether the switch even had a problem, because after several

assemble and check of rotation, cams and switch pointer, all of the sudden I turned the switch and the shaft dd not turn. Then the screw

to tighten the clamp around the shaft becomes obvious.

This leads me to believe that the original problem was the knob rotating around the six sided shaft feeling like a detent, and not switch contacts.

I run the machine on 120Vac.

Now I'm trying to reassemble the 4 section switch with 12 springs and 16 separate contacts that need to be put into place.

And then the cams also need to be installed properly, however, I think they are all in the same orientation, so that may be easy.

AC---Hot and Neutral come in on two connections and on the opposite side are 4 connections that go to the motor.

I can probably do this* if someone can give me a drawing with 4 wires from a motor wired for 120Vac showing how

forward and reverse are implemented. Even if it uses 2-SPDT switches to show the wiring.

Can someone make or find a drawing of such.

**Assumes parts don't go flying more times than I can find them. Already lost a spring but the junk draw had one.

I've searced the carpet for a part 5 times already.