-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Henry Ford's Kitchen Sink Engine (my version)

- Thread starter rdean

- Start date

- Joined

- Feb 2, 2014

- Messages

- 1,068

I did have some run times of about 30 seconds on the engine today and many at 10 seconds but it was running so badly I just stopped trying to start it. I am going to rethink the exhaust valve setup I have as that seems to be where the most problems are.

Give me a day or two and I will be back with an update.

Thanks for looking

Ray

Give me a day or two and I will be back with an update.

Thanks for looking

Ray

- Joined

- Jul 6, 2022

- Messages

- 498

The gas tank is glued up and ready for use.

View attachment 462444

Cutting out the gas tank support.

View attachment 462445

Right off the mill.

View attachment 462446

Drilled some mounting holes, cut a slot, and one hole for the clamp.

Gave it a little polish and here they are installed with the remote fuel needle.

View attachment 462447

Next will be the throttle.

Thanks for looking

Ray

Have you a CNC mill, or did you cut that out on a manual mill?

Sent from my iPhone using Tapatalk

- Joined

- Feb 2, 2014

- Messages

- 1,068

I have an idea that may work and not drastically change the appearance or the spirit of the engine.Yes, the exhaust valve sealing is tricky.

I have a CNC mill that I built several years back. It is very handy for one offs but I still prefer my manual mill for most things,Have you a CNC mill, or did you cut that out on a manual mill?

Thanks for the comments.

Ray

- Joined

- Feb 2, 2014

- Messages

- 1,068

I had always been suspect of the exhaust valve setup that I originally made for the engine. I had a great deal of trouble getting the valve stem hole exactly in line with the valve seat. It looks like it would be a simple thing to do with the six sides flanges on each end of the housing but those flats don't line up with the internal seat or even with each other. So i tried drilling through the valve stem but the inside of the stem is not at 90 degrees to the internal seat.

So this is what I did.

I drilled a large hole through the seat and through the bottom of the valve. I turned a brass slug to be pressed into this hole and cut a valve seat into the end of it. Now the valve seat and the center hole for a new valve are in line with each other. I drilled four holes in the slug to let the exhaust gasses exit and this is how it turned out.

This was a great improvement and I had several short runs but I noticed that when the engine fired there was a puff out the carb. That needs to be addressed so now I will work on the intake valve design.

Thanks for looking

Ray

So this is what I did.

I drilled a large hole through the seat and through the bottom of the valve. I turned a brass slug to be pressed into this hole and cut a valve seat into the end of it. Now the valve seat and the center hole for a new valve are in line with each other. I drilled four holes in the slug to let the exhaust gasses exit and this is how it turned out.

This was a great improvement and I had several short runs but I noticed that when the engine fired there was a puff out the carb. That needs to be addressed so now I will work on the intake valve design.

Thanks for looking

Ray

- Joined

- Feb 2, 2014

- Messages

- 1,068

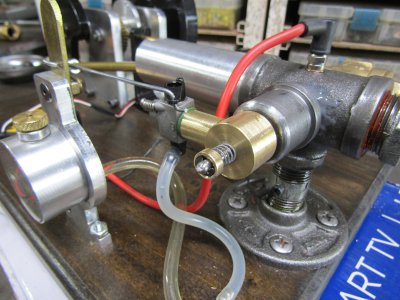

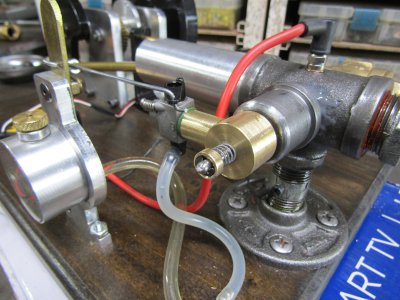

I decided to change the intake valve system completely. I know that this is not how Ford did it but I want an engine that is easy to start and runs somewhat smoothly.

Here are the parts.

And installed.

I did a couple of short runs and then I started hearing an extra clicking sound. If you remember a while back the cylinder had turned and was binding on the piston and the connecting rod. I took that all apart and re tightened along with Lok-Tite and that is staying where it should.

Now the flywheel end is turning.

If you sight down the flywheel you can see how far the housing has turned.

The bright spot on the crankshaft shows where the connecting rod lock nut was hitting and making the racket.

I realigned the housing and secured it with three 5/16" bolts really torqued down.

That should hold it.

Thanks for looking

Ray

Here are the parts.

And installed.

I did a couple of short runs and then I started hearing an extra clicking sound. If you remember a while back the cylinder had turned and was binding on the piston and the connecting rod. I took that all apart and re tightened along with Lok-Tite and that is staying where it should.

Now the flywheel end is turning.

If you sight down the flywheel you can see how far the housing has turned.

The bright spot on the crankshaft shows where the connecting rod lock nut was hitting and making the racket.

I realigned the housing and secured it with three 5/16" bolts really torqued down.

That should hold it.

Thanks for looking

Ray