The HF model is a Chinese clone of the RF-30 and in appearance looks almost identical but I suspect the build quality will not be as good as the Taiwanese RF models. I have not used a Chinese model before so I don't know how good or bad they really are vs the real thing, sorry. But on to your question ...

What is the consensus on the usefullness of this machine?

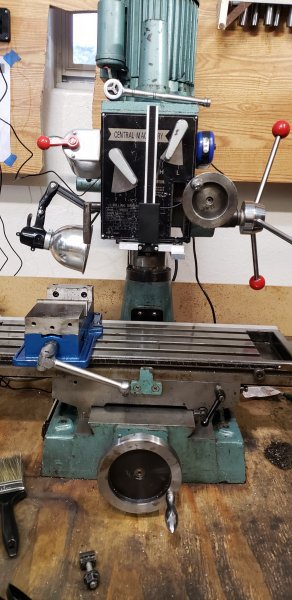

See all the above. You are going to find a lot of detractors regarding round column mills, many of whom have never even seen one in the flesh. For those of us who have lived with them, or at least myself, I think they are quite adequate for a hobby shop. Think about this - you have an 800# machine (weight of the machine plus the stand), 200# of it in the head that rides on a 4-1/2" diameter heavy cast iron column. It has a 3" diameter quill with 5" of travel, and that travel is useful under both radial and axial loads. I don't know how accurate the spindle is on a Chinese machine but I do know that you can replace the bearings pretty easily to greatly improve the run out.

The design of these mills is essentially identical to an Asian drill press but the castings and components are considerably larger and more rigid. There is about 14" of travel up and down the column; while not huge, it is useful as it is. The head does swivel side to side, which can be very handy at times. It is true that you cannot drill the end of a long work piece but think about how often you've had to drill or mill the end of a really long piece and make up your own mind.

Much is made about the round column but to be very honest, I haven't found that to be a major issue at all. Once I start work, I rarely need to move the head so this is not a big deal to me. I'm currently installing the True Line 8 that is supposed to maintain orientation of the head as it moves on the column but I'm not sure just how useful it is because as I said, this head movement thing is a minor issue.

If these mills have a major con, I would have to say that the accuracy of the leadscrews, leadscrew nuts, hand wheels and gibs are not as smooth or accurate as I would like. The gibs are the antiquated tapered style that can be finicky to adjust properly. There is more backlash in the leadscrew nuts than I would like, even though they are adjustable for this. They work but are less precise than I would like. This makes a DRO almost a must-have on these machines if you need to do accurate work.

Will it replace a drill press? Yes, for most work, this kind of machine will replace a drill press because it is, essentially, a drill press. It is also much, much more. But, just like a drill press, it also requires belt position changes to change speeds if that matters to you.

So, yes, it is a useful machine. In the 5 years I've owned mine, it has done all I've asked of it without a single problem. It is big enough and accurate enough for my needs. I would not trade it unless I found a small knee mill in pristine shape; until then, it stays.