- Joined

- Jun 12, 2014

- Messages

- 4,822

If you are turning to a shoulder or threading to a particular point you want the lathe to stop at that position. If you are threading and then need to reverse the cutter, you back out the cutter, press the bypass button and reverse the carriage. I thread at 250-600 RPM, often to a shoulder, there is no way to do this repetitively and have the cutter stop repeatably within 0.001". When doing any thype of threading I do not disengage the half-nut until I am done threading, which usually can be completed in under a minute. Also for blind boring and turning to a shoulder. It is also a safety feature when turning close to the chuck, then getting distracted and crashing your lathe. If you do not want to use it, you can add a jumper at the control panel and remove the P-sensor.

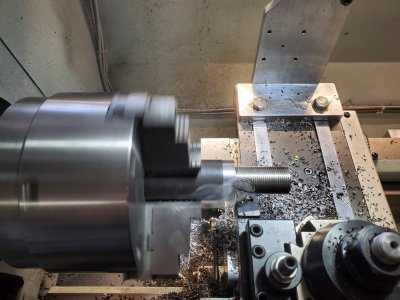

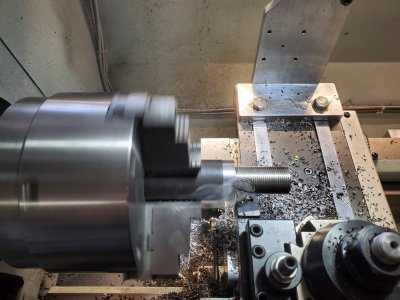

Threading 1144 steel rod 1-14 at 300 RPM to a shoulder, 9 passes to a depth of 0.098".

Threading 1144 steel rod 1-14 at 300 RPM to a shoulder, 9 passes to a depth of 0.098".