- Joined

- Apr 8, 2013

- Messages

- 1,979

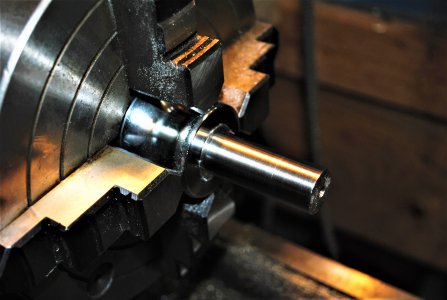

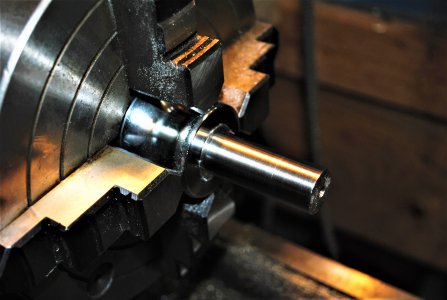

Dispersed between my sons and I are all kinds of tow behinds like mixers, mowers, rollers, trailers, log splitters, ect. As we're always passing these around between us we adapt everything to 2 inch tow balls so everybody always shows up with the right hitch. My quad has a welded on mount for a hitch but it only has a 5/8 hole while the only 2 inch balls I could find needed a one inch hole. I went to turn down the shaft on the 2 inch ball to 5/8 but discovered the ball was bigger than the base flange and I couldn't hold it. I had to turn a flat spot on the ball so it matched the base flange then flip it around so I could turn down the shaft to 5/8 and single point it to 5/8 x 11. Two hours later I finished the job I told my wife was gonna take 15 minutes. Why do these things always happen to ME?

Last edited: