- Joined

- Mar 3, 2020

- Messages

- 195

Hi,

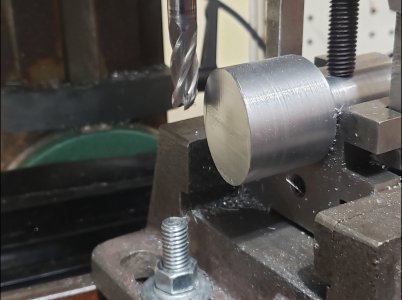

I'm making a fly cutter. 3/4" shank, 1-3/8" body, and will use a 1/4" HSS bit.

How would you hold this V-block at about 10 degrees (angle not critical) to mill a 1/4" slot and cut clearance for screws?

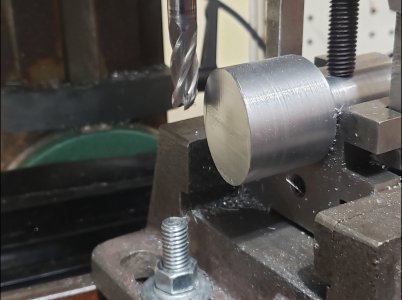

Orienting at an angle in the "drill" style vise didn't work out well, and for the facing operation I re-positioned it as shown in the 2nd image, to use the side of the end mill. That worked alright.

Now I need to cut the slot for the bit and a relieved face for set screws.

I didn't try it tonight but I'm thinking perhaps set up 123 blocks as an angle plate and try to clamp to the 123 blocks with the b-block turned 10 degrees.

The other option I can think of - though I don't currently have the tooling, is to leave the part positioned as-is, and cut the slot with a 1/4" slitting saw. And cut the relief for the set screws with the end mill as shown in the photo. I think I prefer this option in terms of confidence in the setup not moving, but would appreciate any suggestions or other ideas. Thank you!

I'm making a fly cutter. 3/4" shank, 1-3/8" body, and will use a 1/4" HSS bit.

How would you hold this V-block at about 10 degrees (angle not critical) to mill a 1/4" slot and cut clearance for screws?

Orienting at an angle in the "drill" style vise didn't work out well, and for the facing operation I re-positioned it as shown in the 2nd image, to use the side of the end mill. That worked alright.

Now I need to cut the slot for the bit and a relieved face for set screws.

I didn't try it tonight but I'm thinking perhaps set up 123 blocks as an angle plate and try to clamp to the 123 blocks with the b-block turned 10 degrees.

The other option I can think of - though I don't currently have the tooling, is to leave the part positioned as-is, and cut the slot with a 1/4" slitting saw. And cut the relief for the set screws with the end mill as shown in the photo. I think I prefer this option in terms of confidence in the setup not moving, but would appreciate any suggestions or other ideas. Thank you!