- Joined

- Aug 13, 2016

- Messages

- 16

No, sorry Weldo I don't. I've always been rather delinquent when it comes to documenting things.This is pretty rad!

You wouldn’t happen to have any pics of your lathe set up to cut the teeth would you? I was just thinking about maybe possibly considering looking at building an arbor press.

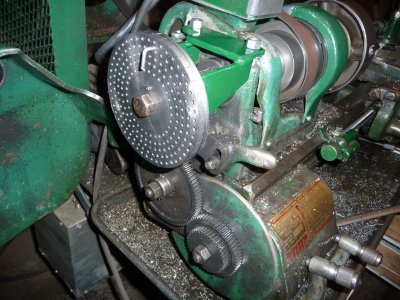

I cut the rack with a fly cutter in a bar mounted in the lathe between the head stock and tail stock.

The pitch was maintained by using a shim between the carriage and an adjustable stop for each cut.

The rack was clamped in a home made milling fixture mounted in place of the turret and elevated through the fly cutter each pass.

I had to flip the rack at one point as the bar with the cutter wasn't long enough and the tail stock was interfering.

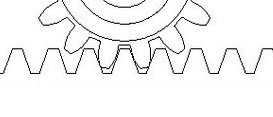

The pinion gear was cut in the lathe as well with a home made indexer and key way cutter.