- Joined

- Aug 5, 2018

- Messages

- 261

Hello again,

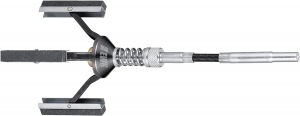

I'm building a small steam engine and I'm going to be boring the cylinder to a specific size of 0.625"

I need to hone this cylinder and while looking online for a hone of that size (which I found much to my disbelief) they mentioned a finish of 35-50 Microinch(.9-1.4 Micrometer) (is this 0.9-1.4 thousands of an inch?) and this made me think that I might need to bore the cylinder undersize to allow for material removal.

Honing a cylinder is new to me and I have only one shot to get it right so please let me know if I'm understanding this correctly.

Thank you,

Michael

I'm building a small steam engine and I'm going to be boring the cylinder to a specific size of 0.625"

I need to hone this cylinder and while looking online for a hone of that size (which I found much to my disbelief) they mentioned a finish of 35-50 Microinch(.9-1.4 Micrometer) (is this 0.9-1.4 thousands of an inch?) and this made me think that I might need to bore the cylinder undersize to allow for material removal.

Honing a cylinder is new to me and I have only one shot to get it right so please let me know if I'm understanding this correctly.

Thank you,

Michael