-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do I

- Thread starter junk iron

- Start date

- Joined

- Jul 2, 2014

- Messages

- 7,594

I would mill it with the shaft mounted in a collet block mounted in the chuck.Hey fellows

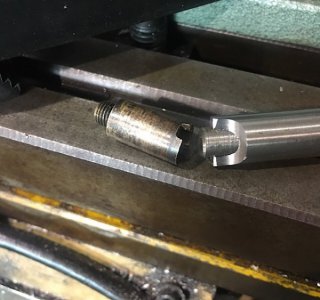

I’m wanting to make a tool to remove the float seat from a carburetor with a pilot that will go down in the seat, the seat has two notches.140 wide for screw driver what’s the best way to machine for lugs on tool?

Thanks View attachment 272783View attachment 272784

- Joined

- Feb 8, 2014

- Messages

- 11,144

I was wondering how it could be done without drilling,but I may have to drill

That being the case, just mill the screwdriver flats with the pilot in place. The pilot doesn't have to be round for it to work properly.