-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How Do You Efficiently Grind A Hss Boring Bar

- Thread starter tomw

- Start date

- Joined

- Dec 6, 2022

- Messages

- 54

Good day, I'm Ken I'm new to the hobby and the site. I was told when I first joined to watch / read thread or video on HSS tooling somone had spent time putting together.... I chose to try and fail myself at first.. however , I'm interested in making a boring bar out of HSS. I saw this your post. I hit ' watch" and I couldn't seem to get anything to watch. Would u happen to know what I'm doing wrong or what i need to do to view the information? I've also tried to watch other videos on this site and couldn't. Do I need to pay? If so who?Dear All,

This post is really two questions. The first is how do go about grinding a boring bar in a way that does not take a weekend. The second questions is what is the optimal shape for a boring bar.

For the first question:

I need to make a boring bar to enlarge a 3/8" diameter x 1 7/32 length core hole in a bronze casting.

I have 1/4" HSS tool bit stock.

I am grinding the tool bits on the wheels that originally came with my 6" Jet bench grinder. They have worked fine (as far as I know) for grinding regular lathe tool bits. One is coarse, one is less coarse. Both wheels were dressed before commencing the operation.

I spent 45 minutes removing 1/32" of material from 1-3/8" of said HSS stock, picking that side as the "bottom" of the bit. According to my math, I need to remove at least another 1/32" for clearance on just the bottom of the bar. Am I consigned to spending the next 4 hours making a boring bar?

Second question:

What is the optimal shape for a HSS boring bar ground from square stock to enhance rigidity while maintaining clearance?

So, where do you grind the clearance. Do you take some off the top, of just the leading side, or where?

I have done the Google and BoobTube thing, and have not found any good answers. I also can't find answers in Machinery's, though this may be to unfamiliarity with the index and table contents.

Thank you all for your help.

Cheers,

Tom

Sorry for the late inquiry.

Thanks

Ken

- Joined

- Dec 20, 2012

- Messages

- 9,422

When I first started in this hobby, I ground some bars from HSS square stock; lots of work. Then I turned bars from O-1 steel, ground the clearance angles I needed, then hardened and tempered them. All worked okay but had the key limitation of being made of steel, with the extension limits thereof.

Today, I would not grind a boring bar. I would buy a set of cobalt bars or perhaps a solid carbide bar from a good maker like Micro 100. They will work every time and, if cared for, will last a lifetime.

Lathe tools are another matter. Those I would learn to grind.

Today, I would not grind a boring bar. I would buy a set of cobalt bars or perhaps a solid carbide bar from a good maker like Micro 100. They will work every time and, if cared for, will last a lifetime.

Lathe tools are another matter. Those I would learn to grind.

There are several ways to go about this depending on the material to be cut and the size of the bore. However as mikey mentioned it is 'a lot of work' and there are options other than grinding a piece of square HSS to be aware off.I'm interested in making a boring bar out of HSS.

I have had some success using cement nails and grinding the head to the dimensions required. It is much easier than grinding a boring bar from a square piece of HSS.

There are some small boring bars on the market that might do as well.

BORING BAR SET 4PC 1/4IN. 5/16IN. 3/8IN. 1/2IN.

Busy Bee Tools is Canada's largest Woodworking & Metalworking retailer. Find power tools, woodworking tools & metalworking tools at factory direct prices.

www.busybeetools.com

www.busybeetools.com

Last edited:

Did you click on the link in post #19?I couldn't seem to get anything to watch.

- Joined

- Dec 6, 2022

- Messages

- 54

Did you click on the link in post

When I first started in this hobby, I ground some bars from HSS square stock; lots of work. Then I turned bars from O-1 steel, ground the clearance angles I needed, jlthen hardened and tempered them. All worked okay but had the key limitation of being made of steel, with the extension limits thereof.

Today, I would not grind a boring bar. I would buy a set of cobalt bars or perhaps a solid carbide bar from a good maker like Micro 100. They will work every time and, if cared for, will last a lifetime.

Lathe tools are another matter. Those I would learn to grind.

- Joined

- Dec 6, 2022

- Messages

- 54

I agree and I am looking to buy some boring bars. But I picked up a 18 pack of used hss , some ground some blanks and I'm interested in making my own with a blank.

I can't seem to watch anything on this site. I doing it wrong ? Do I need to pay indont understand why I struggle with this platform. Lol. I can't seem to watch any videos or whatever.

I would like grind several tool. I noticed in several lots of hss tooling many have the same unique shapes , over and above urncommon Turing, facing shapes. I have several blanks and I'm interested in grinding a few tools for my own experience.

Since indont have any boring bars yet I wanted to grind one or 2 for fun.

I can't seem to watch anything on this site. I doing it wrong ? Do I need to pay indont understand why I struggle with this platform. Lol. I can't seem to watch any videos or whatever.

I would like grind several tool. I noticed in several lots of hss tooling many have the same unique shapes , over and above urncommon Turing, facing shapes. I have several blanks and I'm interested in grinding a few tools for my own experience.

Since indont have any boring bars yet I wanted to grind one or 2 for fun.

- Joined

- Dec 6, 2022

- Messages

- 54

I'll buy some. I'm just interested in grinding my own tools forn the experience. Not all just a few. I don't have have a boring bar yet amd inhave several blanks .There are several ways to go about this depending on the material to be cut and the size of the bore. However as mikey mentioned it is 'a lot of work' and there are options other than grinding a piece of square HSS to be aware off.

I have had some success using cement nails and grinding the head to the dimensions required. It is much easier than grinding a boring bar from a square piece of HSS.

There are some small boring bars on the market that might do as well.

Hope you enjoy your learning experience.

BORING BAR SET 4PC 1/4IN. 5/16IN. 3/8IN. 1/2IN.

Busy Bee Tools is Canada's largest Woodworking & Metalworking retailer. Find power tools, woodworking tools & metalworking tools at factory direct prices.www.busybeetools.com

I also noticed on several used lits of hss tools that there are some unique tools and I see them come up in differnt lots of used hss. Some.i have no idea if they are a tool or a mistake.

I think it would be fun to grind tools.. I've done a couple reg turning tools.

I recently picked up a mixed lot if hss on ebay and got a few tools thst I've never seen before. I'll post picks one night. But I'm very interested In grinding a few smaller blanks ad practice.

Any info on this sight to help? O can't seem to watch anything. How to I watch? I hit ' watch" nothing happens

Thanks

- Joined

- Dec 6, 2022

- Messages

- 54

Buying the tool is easy. I'm interested in grinding tools. I have ground a few turning tos I want to try a boring bar. I have a smaller piece of round hss and it will be funThere are several ways to go about this depending on the material to be cut and the size of the bore. However as mikey mentioned it is 'a lot of work' and there are options other than grinding a piece of square HSS to be aware off.

I have had some success using cement nails and grinding the head to the dimensions required. It is much easier than grinding a boring bar from a square piece of HSS.

There are some small boring bars on the market that might do as well.

Hope you enjoy your learning experience.

BORING BAR SET 4PC 1/4IN. 5/16IN. 3/8IN. 1/2IN.

Busy Bee Tools is Canada's largest Woodworking & Metalworking retailer. Find power tools, woodworking tools & metalworking tools at factory direct prices.www.busybeetools.com

Also. I'm new and I've noticed that tools are either hss ( tool steel i assume) and cobalt and tungsten. What's the difference between these?? I know cobalt amd tungsten are types of metals in the periodic table. How to tell them apart and which are better for what??..

Thanks

Ken

- Joined

- Sep 5, 2013

- Messages

- 3,207

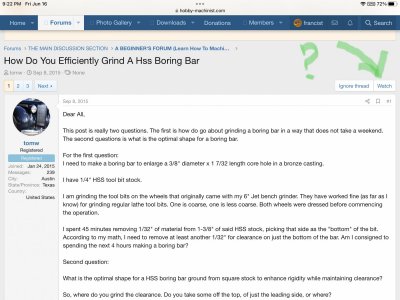

Hi Ken, I’m sorry you’re having so much trouble finding what you’re after. I am curious though, and you’ve mentioned this a couple of times, what “watch” button are you hitting to try and watch a video? Would it by any chance be the one in the upper right at the top of a thread? I’ve put a picture below with a big green arrow pointing to that button — is this the one you’ve been poking to try to ‘watch’ video content on the site?Any info on this sight to help? O can't seem to watch anything. How to I watch? I hit ' watch" nothing happens

Im sorry if I’m way off base here, but it just struck me as a possibility so I thought I would at least try to clear one thing of the table at least.

-frank