-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do you Setup a Taig 4 Jaws Chuck?

- Thread starter oskar

- Start date

- Joined

- Nov 4, 2015

- Messages

- 47

I was hoping to try the lathe first with some easy tasks to get the hang of it and then go to more difficult tasks.

You can still use the scroll Chuck, just realise that until it's square, you won't be able to turn anything coaxial to the part inside the Chuck.

The work will still turn true and cylindrical, you will just need to remove a little more material at the start.

It's all good!

Although I do love a 4 jaw independent Chuck. They take more time to dial in, however I enjoy the process.

- Joined

- Nov 17, 2017

- Messages

- 1,525

The trick to getting tight tolerances on the Taig is to put something round (like a dime) behind the jaws so there is equal tension on each jaw before skimming the nose of the jaw.

- Joined

- Nov 24, 2013

- Messages

- 254

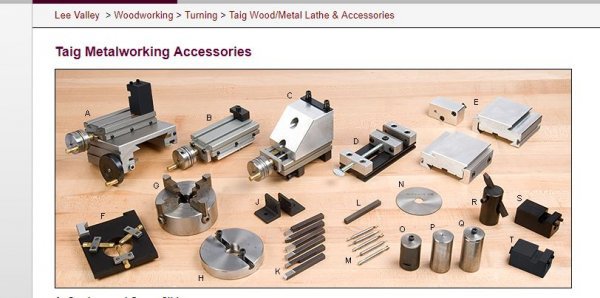

Thanks Frank, I'm looking at this item and I may go for it, about $120 with taxes/ shipping

I was unable to take appart my chuck because it has at the back a circ clip 1.75" diameter and my circ clip tool does not open so much. Anyway I also noticed that the jaws were not screwed in fully and after cleaning the jaws and screw them properly now the wobble is not noticable and my dial meter shows a variance of 0-10 thousands. Not the best but much better than before

I was unable to take appart my chuck because it has at the back a circ clip 1.75" diameter and my circ clip tool does not open so much. Anyway I also noticed that the jaws were not screwed in fully and after cleaning the jaws and screw them properly now the wobble is not noticable and my dial meter shows a variance of 0-10 thousands. Not the best but much better than before

- Joined

- Jun 29, 2014

- Messages

- 4,059

I have the 4 jaw scroll chuck for the Taig. You can grind a small bit to true up the jaws and you will be fine. I found that after truing, you can snug the jaws up on your work piece and then get it to run with little to no runout. The Taig's are nice little machines and you can do close work if you take your time with them. You said you haven't used a lathe much. Truing up the jaws will get you more familiar with the lathe operations. Also check your chuck jaws to make sure they are seated properly. I found that the soft jaws can get a little marred up if you change them frequently and this can lead to them not going back on 100% square.

- Joined

- Nov 24, 2013

- Messages

- 254

I have the 4 jaw scroll chuck for the Taig. You can grind a small bit to true up the jaws and you will be fine. I found that after truing, you can snug the jaws up on your work piece and then get it to run with little to no runout. The Taig's are nice little machines and you can do close work if you take your time with them. You said you haven't used a lathe much. Truing up the jaws will get you more familiar with the lathe operations. Also check your chuck jaws to make sure they are seated properly. I found that the soft jaws can get a little marred up if you change them frequently and this can lead to them not going back on 100% square.

Thank you Bryan

I have used the lathe along with the compound slide (which I converted to a milling slide) to mill some slots in aluminum but I never used the lathe yet for any other purpose. I have some 1/4” square HSS stock and I will make a boring bar and do try to fix the jaws.

I contemplate to get the 4 independently adjusted chuck part #1030 or the 3 scroll type jaws part #1050. Do you have any experience with either one to share? If you had to buy one which one would you say is the most versatile?

Nicolas

- Joined

- Jun 29, 2014

- Messages

- 4,059

To say that one is more versatile than the other is a matter of opinion. 3 jaw scroll chucks are simple to use for round stock or hex stock. 4 jaw scrolls are great for turning square stock (provided you are happy with their accuracy - topic of this thread) A 4 jaw independent chuck as already mentioned is for entirely different purposes - like off center holding.

I also have the two chucks you mention for my Taig. They also fit my 109 which is nice. All of them have their own value in terms of how useful they are to you. One of the things about machining I love is the infinite number of tooling ideas available to us.

I sent you a PM - I have a PDF document that I can share with you on chuck restoration - let me know if you would like to take a look.

I also have the two chucks you mention for my Taig. They also fit my 109 which is nice. All of them have their own value in terms of how useful they are to you. One of the things about machining I love is the infinite number of tooling ideas available to us.

I sent you a PM - I have a PDF document that I can share with you on chuck restoration - let me know if you would like to take a look.

A 4 Jaw independent chuck is the only way that work such as this can be done in a lathe. The bore is off center in one plane.

This job is drill 1.125" thru 8" then bore each end 1.181" 1.182" X 1.594" deep, the bores have to be concentric within .002". This took me roughly 1 hour of set up per part and 10 minutes of actual machining, this is extremely tedious work..

If you do mostly round work an adjustable 3 Jaw scroll chuck is the way to go. Turn the jaws in place and have at it.

If indeed you are unfortunate enough that your employer hands you all of the off center lathe work you are screwed, 4 jaw independent chucks are useful when needed.

You may also do things like this using different top jaws milled to suit the work.

This job is drill 1.125" thru 8" then bore each end 1.181" 1.182" X 1.594" deep, the bores have to be concentric within .002". This took me roughly 1 hour of set up per part and 10 minutes of actual machining, this is extremely tedious work..

If you do mostly round work an adjustable 3 Jaw scroll chuck is the way to go. Turn the jaws in place and have at it.

If indeed you are unfortunate enough that your employer hands you all of the off center lathe work you are screwed, 4 jaw independent chucks are useful when needed.

You may also do things like this using different top jaws milled to suit the work.