- Joined

- Jan 10, 2019

- Messages

- 1,042

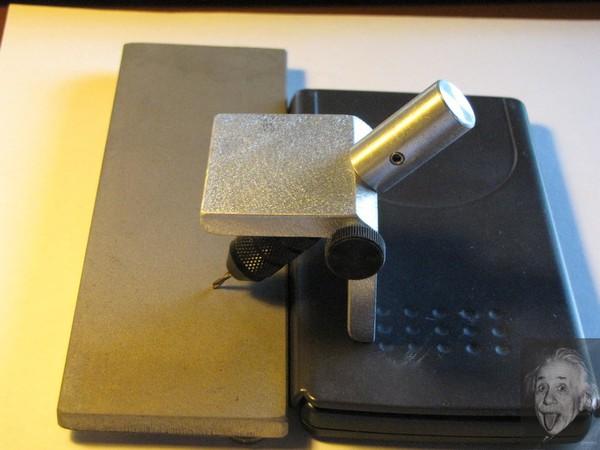

Drill Doctor 750, though I had to watch some YouTube videos because the sharpener was producing disappointing results. Oddly, several settings have to be moved away from the Drill Doctor's own recommendations to make the drills work like they should.