Trying to indicate a 26 inch flange on a VTL 3 jaw. Can someone refresh me on the 4 point method trying to get two points across from each other close as possible. Then the other two points as close as possible . Then rotate chuck for total TIR. The other methode of indicating did not work to far out chasing my tail. Much appreciated for any help.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to 4 point dial indicate on lathe question?

- Thread starter Ktencza

- Start date

- Joined

- Nov 24, 2014

- Messages

- 3,179

Is the 3 jaw an independent or a scroll chuck?

If it's an independent, why not indicate at 3 points, one each near each jaw.

If that's not a useful answer, I need a better understanding of the problem.

If it's an independent, why not indicate at 3 points, one each near each jaw.

If that's not a useful answer, I need a better understanding of the problem.

I never tried that way. Maching a gasket surface on a heat exchanger nozzle 26 inches, came from a fitter not so fit . The traditional way of indicating its out .080 best i could get.. At most i am allowed 0.030. I recall doing a four point method a year or so ago two points 180 apart, then the other two points. What your speaking of try three jaw method? Just try to get each jaw as close as i can to each other when indicating correct?

- Joined

- Nov 24, 2014

- Messages

- 3,179

Trying to indicate a 26 inch flange on a VTL 3 jaw. Can someone refresh me on the 4 point method trying to get two points across from each other close as possible. Then the other two points as close as possible . Then rotate chuck for total TIR. The other methode of indicating did not work to far out chasing my tail. Much appreciated for any help.

Why do people with questions decline to answer questions asked of them?

Is the 3 jaw an independent or a scroll chuck?

- Joined

- Jan 20, 2018

- Messages

- 5,639

Since it is a 3-jaw, I would do as @extropic suggested and indicate at each jaw. Trying to indicate 4 points on a 3-jaw chuck can be challenging and frustrating. Is the part actually round or just roughly so?

- Joined

- Oct 7, 2020

- Messages

- 2,116

You are trying to dial in the face of the flange, right? I guess I would have to see a photo, but if that's the case. Don't seat it against the back of the chuck, in my experience it makes it easier to tap it in to square.

Disclaimer: I'm still a beginner, so take what I say with a grain of salt. LOL

Disclaimer: I'm still a beginner, so take what I say with a grain of salt. LOL

- Joined

- Feb 1, 2015

- Messages

- 9,622

Adjusting a four jaw chuck for runout works because the two sets of jaws are independent. You loosen one jaw and tighten the opposite jaw.

With a three jaw chuck, you will loosen one jaw and have to tighten the two remaining jaws equally or you will throw the adjustment out in the perpendicular direction. This complicates the alignment process but it can be done.

With a three jaw chuck, you will loosen one jaw and have to tighten the two remaining jaws equally or you will throw the adjustment out in the perpendicular direction. This complicates the alignment process but it can be done.

- Joined

- Apr 16, 2019

- Messages

- 745

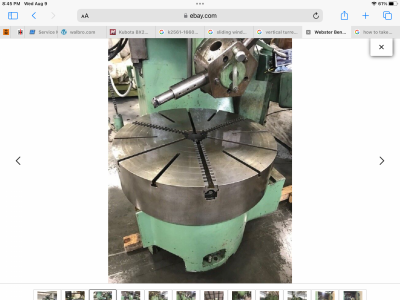

I’m thinking you’re using a VTL like this ? Can the flange be just clamped to the table ? If so you can use a scribe ( nail in a block of wood too ) tap it close then use an indicator. If you only had jaws to work with use the same method and set the indicator at one jaw and bring it till it just touches and repeat to the others .