-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How To Cut These Angled Slots?

- Thread starter Machinehead

- Start date

- Joined

- Sep 29, 2014

- Messages

- 2,102

You would grind the angle on the saw which is easily done.If you tilt the head you can not get a flat bottom cut.

- Joined

- Feb 1, 2015

- Messages

- 9,619

The tilting rotary table would make it easy. Tilt the table to 35º parallel to either the x or y axis. Cut along that axis with a slitting saw. Rotate the RT 90º and repeat., etc.

If you don't have access to a tilting RT, a sine plate can be used to set the 35º angle.

If you don't have a sine plate, you could create the angle by clamping a bar to the table to act as a stop and building up the opposite end by placing a piece of round stock in a vee block and clamping the vee block with suitable stacked spacers to create the necessary angle. Once the setup is done, clamp the RT in place and cut your slots.

If you don't have access to a tilting RT, a sine plate can be used to set the 35º angle.

If you don't have a sine plate, you could create the angle by clamping a bar to the table to act as a stop and building up the opposite end by placing a piece of round stock in a vee block and clamping the vee block with suitable stacked spacers to create the necessary angle. Once the setup is done, clamp the RT in place and cut your slots.

- Joined

- Sep 29, 2014

- Messages

- 2,102

The tilting rotary table would make it easy. Tilt the table to 35º parallel to either the x or y axis. Cut along that axis with a slitting saw. Rotate the RT 90º and repeat., etc.

If you don't have access to a tilting RT, a sine plate can be used to set the 35º angle.

If you don't have a sine plate, you could create the angle by clamping a bar to the table to act as a stop and building up the opposite end by placing a piece of round stock in a vee block and clamping the vee block with suitable stacked spacers to create the necessary angle. Once the setup is done, clamp the RT in place and cut your slots.

Much like myself you failed to notice that the bottom of the slot is parallel to the axial plane, this will require a form tool in a mill, EDM will also do this job. For a one off hobby project grinding a slitting saw is the least expensive answer.

- Joined

- Aug 17, 2015

- Messages

- 29

Much like myself you failed to notice that the bottom of the slot is parallel to the axial plane, this will require a form tool in a mill, EDM will also do this job. For a one off hobby project grinding a slitting saw is the least expensive answer.

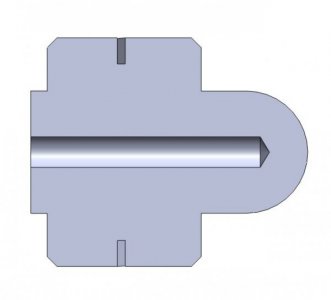

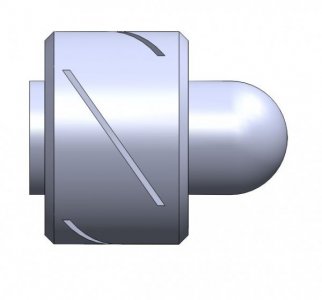

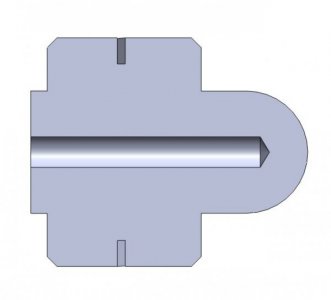

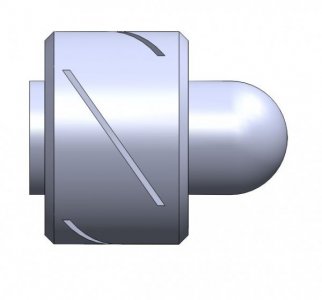

I think the appearance of the slot bottom being parallel to the axial plane is a result of an angled slot intersecting a curved surface. I drew it up in 3D with a flat bottom slot and got the same results. The drawing really need a sectioned view.

- Joined

- Sep 29, 2014

- Messages

- 2,102

Interesting, 35° is a considerable angle, I am surprised that the radius on such a small part would cause this. Post your drawings.I think the appearance of the slot bottom being parallel to the axial plane is a result of an angled slot intersecting a curved surface. I drew it up in 3D with a flat bottom slot and got the same results. The drawing really need a sectioned view.

- Joined

- Aug 17, 2015

- Messages

- 29

- Joined

- Feb 1, 2015

- Messages

- 9,619

Here is a SolidWorks rendition of the OP's part based on his dimensions. The tapped hole was left out and the axial position of the slots wasn't given. Otherwise is should be accurate. The slots were made as would be done with a slitting saw, the edge perpendicular

to the blade face. This is illustrated in the sectional view. As can be seen, the slots appear to be coming out with a bevel. This is due to the curvature of the hub.

to the blade face. This is illustrated in the sectional view. As can be seen, the slots appear to be coming out with a bevel. This is due to the curvature of the hub.

to the blade face. This is illustrated in the sectional view. As can be seen, the slots appear to be coming out with a bevel. This is due to the curvature of the hub.

to the blade face. This is illustrated in the sectional view. As can be seen, the slots appear to be coming out with a bevel. This is due to the curvature of the hub.