-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to determine a drill size for a thread.

- Thread starter Brento

- Start date

- Joined

- Nov 23, 2017

- Messages

- 1,191

I just had to do this the other day... This website is very helpful...

http://www.guhring.com/Tech/tapdrill

edit:

site is down..... lol

http://www.guhring.com/Tech/tapdrill

edit:

site is down..... lol

Last edited:

Guhrings calculator does not calculate the thread dimensions just brings up a list of standard ANSI threads.

The 1.039-40 thread is not listed in the standards and appears to be proprietary to an optics manufacturer, it is likely that this company is not keen on publishing the thread data.

The 1.039-40 thread is not listed in the standards and appears to be proprietary to an optics manufacturer, it is likely that this company is not keen on publishing the thread data.

- Joined

- Nov 23, 2017

- Messages

- 1,191

...

- Joined

- Nov 23, 2017

- Messages

- 1,191

- Joined

- Feb 8, 2014

- Messages

- 11,144

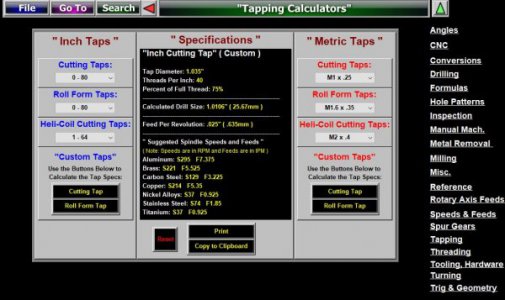

Here is a calculator. http://theoreticalmachinist.com/TapDrillSizeCalculators

There is a formula, but I'm too lazy to look it up

There is a formula, but I'm too lazy to look it up

- Joined

- Oct 8, 2018

- Messages

- 3

Exactly, I used the easy method and it yielded a minor diameter of 1.010 for a 75% thread fit, well within Thor's recommended sizes.

I have not used a tap drill chart in years, I just subtract the lead from the major diameter, this works for all 60° V threads.

I have not used a tap drill chart in years, I just subtract the lead from the major diameter, this works for all 60° V threads.