It is a challenge holding parts some time. With compound it gets slippery. Ive throw my share of parts across the room.  Then having to repolish because of the huge scratch I just put in it.

Then having to repolish because of the huge scratch I just put in it.

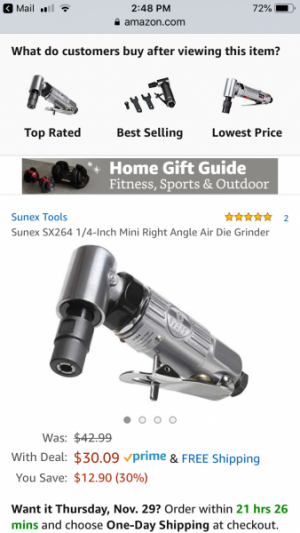

With a lathe I would use a expandable arbor in Chuck then mount your piece. Spin the part and use a drill,or what have you with your buffing wheel and go at it. Will cut time down a lot with spinning part. Here is one tool I use almost every time I polish. Put a 3”x1/2 wide wheel on it. Works great they spin a lot faster than drills and such.

With a lathe I would use a expandable arbor in Chuck then mount your piece. Spin the part and use a drill,or what have you with your buffing wheel and go at it. Will cut time down a lot with spinning part. Here is one tool I use almost every time I polish. Put a 3”x1/2 wide wheel on it. Works great they spin a lot faster than drills and such.