H

Hukshawn

Forum Guest

Register Today

What kind of aluminum oxide belts are you using? I went shopping today. got a wax stick, different brand, meant for threads or grinding etc, but looks like the right stuff. got a new 40 grit belt and a couple discs. I can grind about half a face using about 1/3 of the 4" belt. I get half a face ground and the belt is dull.

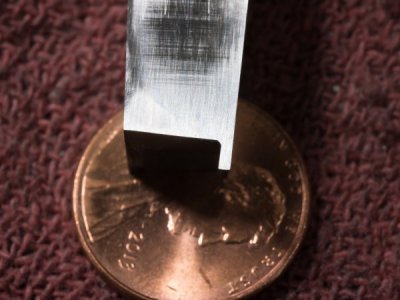

I'm trying to grind a 3/8 hss tool bit, pictured below...

Is this bit super hard? even my grinder is having a hard time. I like these 3/8" bits. the 1/4" ones I have seem to grind nicer...

What am I doing wrong here...

I'm trying to grind a 3/8 hss tool bit, pictured below...

Is this bit super hard? even my grinder is having a hard time. I like these 3/8" bits. the 1/4" ones I have seem to grind nicer...

What am I doing wrong here...