- Joined

- Feb 1, 2015

- Messages

- 9,608

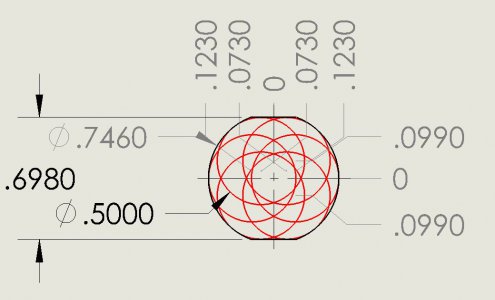

Use the 1/2" You will have to make three passes. Here is a drawing with the coordinates of the start and end points.Okay, here's the dimensions. So, it looks like a 11/16" or 5/8" end mill would work. Of course, I have neither! I only have 1/2" and 3/4" in that range.

View attachment 311362

That's a double-D in metal punch jargon.I'm working on making a panel to mount Aviation-style connectors for my CNC mill conversion.

The ideal cutout would be a circle with two flats on it on opposite sides.