-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make this part

- Thread starter martik777

- Start date

Looks like about $60 + shipping for material. I'm a hobbyist, so really could not devote time if a quick turn around is required. Neither do I think I could do the 1st 30 or so with an average of 7 minutes per part. I'd say, for what machines I have, I'd be doing good to ave over 100 pieces about 15 minutes or less ea. I don't see a good compromise between what I should charge & what you would expect to pay.

Of course Karl_T is right about CNC being quickest & most accurate. I know not what you would expect to pay though.

Of course Karl_T is right about CNC being quickest & most accurate. I know not what you would expect to pay though.

- Joined

- Apr 23, 2018

- Messages

- 6,603

Cheeeit, a 120-year-old B&S screw machine could knock those out in about two or three seconds from bar stock feed, each!

Turn, turn, chamfer, chamfer, part... next!

Turn, turn, chamfer, chamfer, part... next!

- Joined

- Dec 26, 2015

- Messages

- 2,082

- Joined

- Dec 26, 2015

- Messages

- 2,082

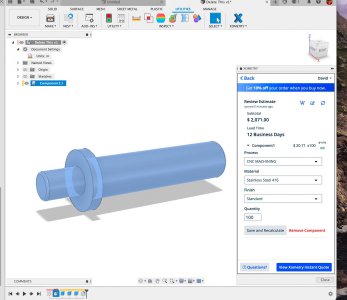

Oh, and that's from a USA source. In a day or so I'll get an actual "firm quote link" after somebody reviews the 3D model, and it will have the ability to source it from China. Past experience suggests this same 100 pieces from Chinese CNC source would be $800-900 (delivered) with a 4-5 week leadtime. I have stopped manually making parts that require 25+ quantity, and started outsourcing it to Xometry (usually USA sourced to support das homeland).

- Joined

- Feb 21, 2022

- Messages

- 779

If you have a manual lathe with DRO then I would use a Seco MDT tool or equivalent and turn the whole thing in one hit with the same tool. Cut the bar into 20" lengths that will fit inside the lathe headstock withot protruding making 19 pieces per length. You should be able to hit under 4 mins per piece. Knock the sharp corners off before parting.

I think 2 or 3 seconds on a 120 year old screw machine is ridiculous.

Edit: Link to tool - https://www.secotools.com/article/676?language=en

I think 2 or 3 seconds on a 120 year old screw machine is ridiculous.

Edit: Link to tool - https://www.secotools.com/article/676?language=en