- Joined

- Oct 16, 2019

- Messages

- 6,577

I have a need to make a 16” long rod with a diameter of .96” and I need to machine a reduced area on one end.

I have some suitable stock at .99”

Problem is I don’t have a steady or follow rest and the spindle bore on my lathe is only .867

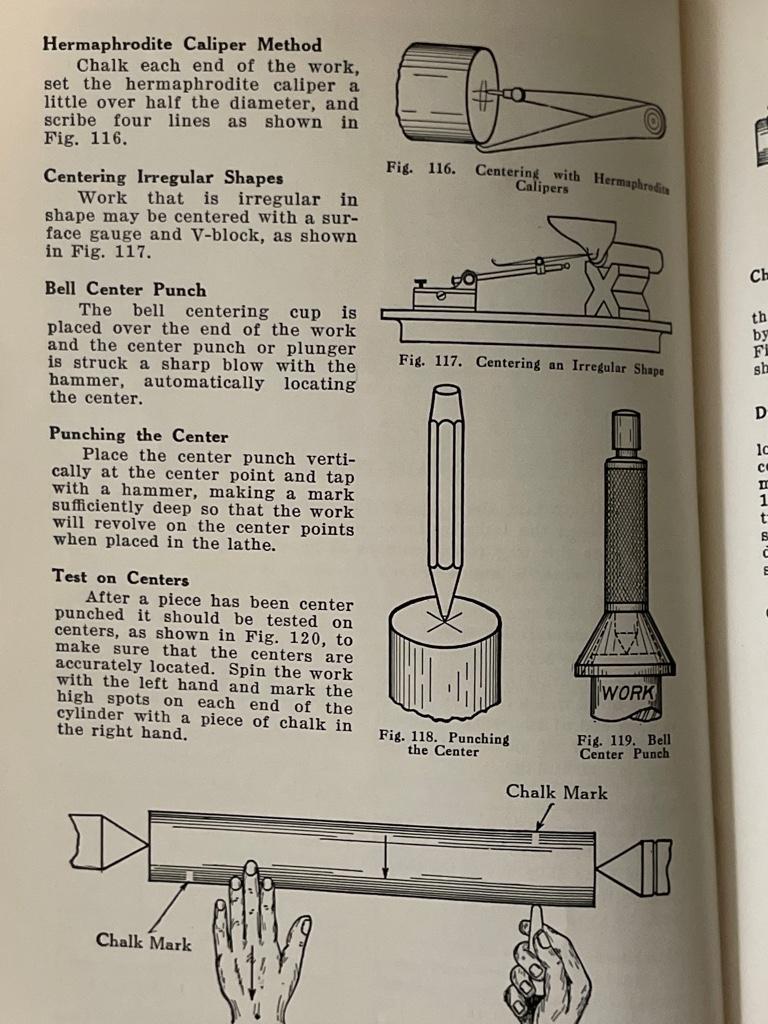

So I’m stuck on how I’d center drill the end for tail stock support.

Any suggestions on how I can do this?

I have some suitable stock at .99”

Problem is I don’t have a steady or follow rest and the spindle bore on my lathe is only .867

So I’m stuck on how I’d center drill the end for tail stock support.

Any suggestions on how I can do this?