- Joined

- Dec 18, 2019

- Messages

- 6,463

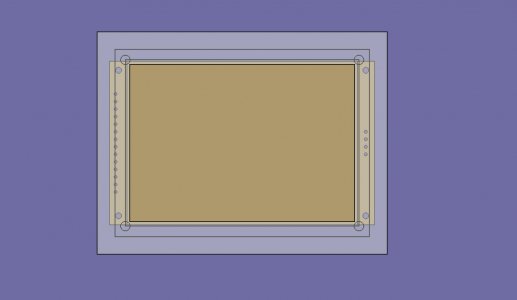

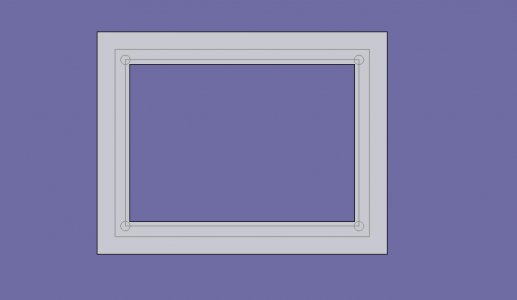

I need to make or buy a bezel to fit a 320 x 240 3.2" diagonal LCD display. Haven't been successful in the search to buy, so was thinking of attempting to machine one. This will be the display for my electronic lead screw controller. I need to keep any chips out of the electronics, so need to cover up the opening in the chassis. One obvious thing would be to 3d print one. That would work if I had one, but I don't have one right now. (Also don't want to spend $400-$1000 on one and spend two months getting a first good print.) So I guess I will have to machine one.

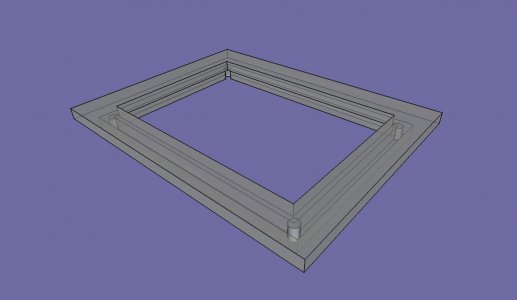

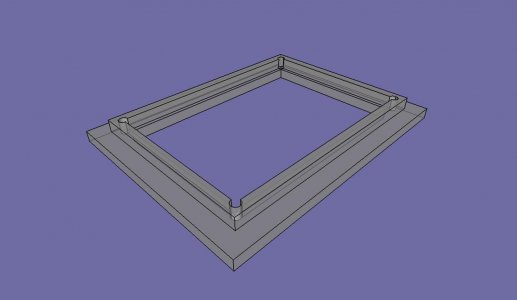

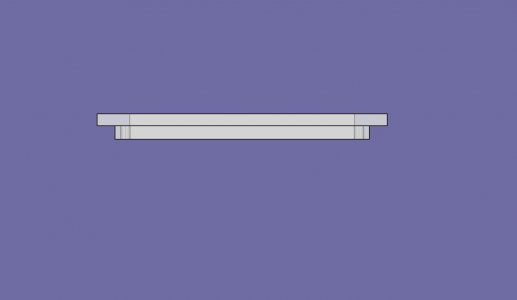

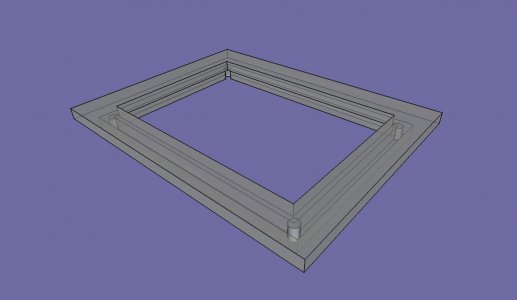

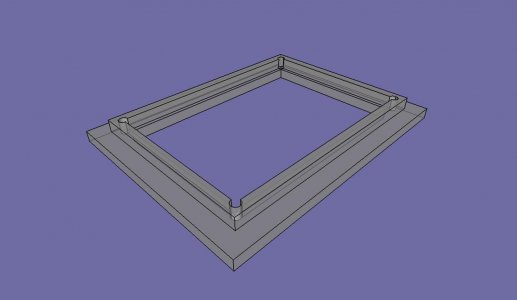

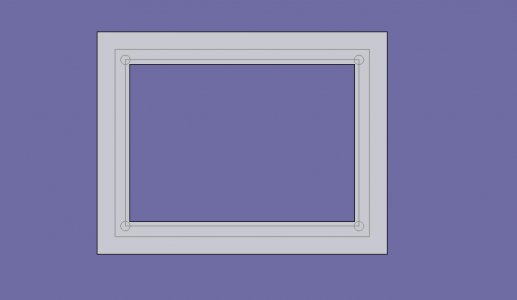

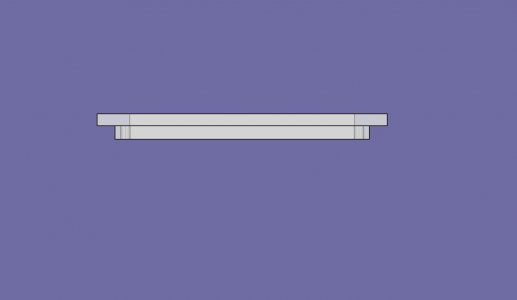

I am presuming some sort of black plastic, although I am open to suggestions. What might be suitable? How do you hold down plastic to mill it without it squirming all over the place? It has 4mm top thickness, extends below the display surface about 4mm and the bottom surround ring is about 4mm thick. How can I get the square inside corners for the display? I put in mouse holes in the inside corners, of the bottom, but those aren't visible. Just file out the rounded corners? I will probably bevel the edges, especially by the display to allow a finger to get close to the edges or corners. Haven't figured out the fasteners just yet. Probably going to be a plastic or metal box of some sort that the bezel and display will fit into. For reference, the LCD display measures 55 x 78 x 5mm.

I can see I need some minor changes to account for the pins and the fasteners for the display board as well. Need to relieve part of the bezel to avoid interference, Or just make it shorter. Worst case, I can swipe it with a mill in those areas.

Any tips on doing something like this would be appreciated.

I am presuming some sort of black plastic, although I am open to suggestions. What might be suitable? How do you hold down plastic to mill it without it squirming all over the place? It has 4mm top thickness, extends below the display surface about 4mm and the bottom surround ring is about 4mm thick. How can I get the square inside corners for the display? I put in mouse holes in the inside corners, of the bottom, but those aren't visible. Just file out the rounded corners? I will probably bevel the edges, especially by the display to allow a finger to get close to the edges or corners. Haven't figured out the fasteners just yet. Probably going to be a plastic or metal box of some sort that the bezel and display will fit into. For reference, the LCD display measures 55 x 78 x 5mm.

I can see I need some minor changes to account for the pins and the fasteners for the display board as well. Need to relieve part of the bezel to avoid interference, Or just make it shorter. Worst case, I can swipe it with a mill in those areas.

Any tips on doing something like this would be appreciated.