- Joined

- Feb 24, 2019

- Messages

- 945

I went to the metal place yesterday hoping to find some remnants of 2.5" X 1.5" aluminum bar stock.

I need to make a couple spacers for connecting a stepper to a ballscrew shaft.

They didn't have any.

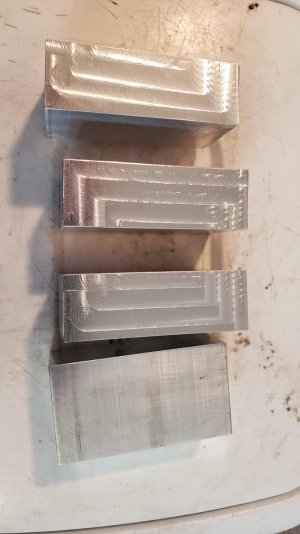

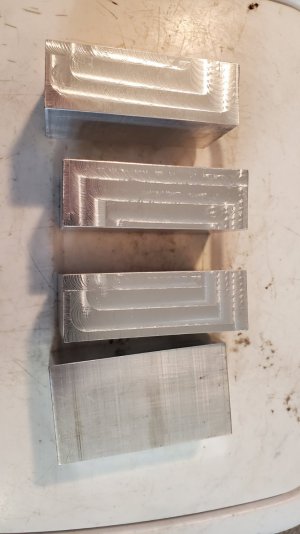

I have a few blocks of aluminum that are much bigger but too small to put into the miter saw. The blocks are big enough that I can get 4x of the size I need out of each block. They're 5.25 x 4 x 1.25

My scroll saw is what I'd normally use but it's buried in it's winter hidey spot. I don't have a band saw, table saw, radial arm saw.

How would you cut these blocks into 4 pieces?

I'm tempted to just segment them with a mill bit. I have to mill them afterwards anyhow.

I need to make a couple spacers for connecting a stepper to a ballscrew shaft.

They didn't have any.

I have a few blocks of aluminum that are much bigger but too small to put into the miter saw. The blocks are big enough that I can get 4x of the size I need out of each block. They're 5.25 x 4 x 1.25

My scroll saw is what I'd normally use but it's buried in it's winter hidey spot. I don't have a band saw, table saw, radial arm saw.

How would you cut these blocks into 4 pieces?

I'm tempted to just segment them with a mill bit. I have to mill them afterwards anyhow.