- Joined

- Dec 10, 2023

- Messages

- 76

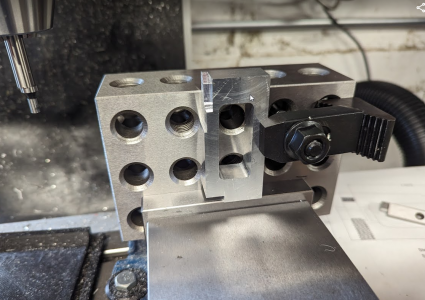

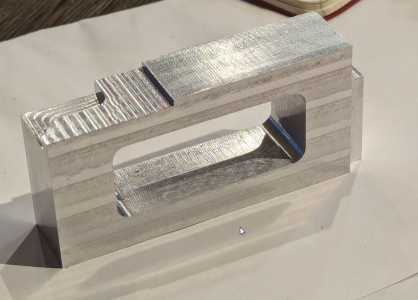

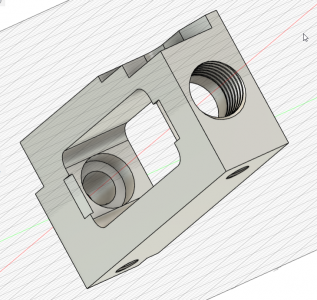

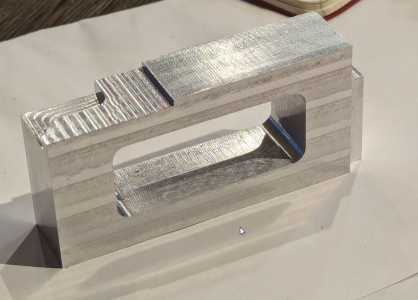

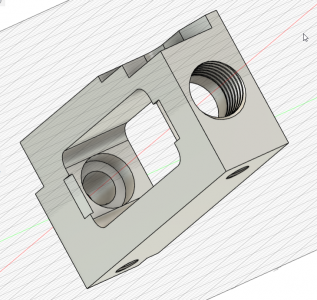

I have this part that i use my little CNC machine to make.

I need to drill/ream and tap it next.

I have a PM728VT mill that i plan to do those operations. With this pocket hole in the middle of the part. What is the best way to hold this part for drilling in the direction i need to go? I dont have a lathe.

I mean i can throw it in my 4" vise with the part sticking up. If you think that is all i need i will continue. It is just a lot of part sticking up and a long hole to drill.

3inch total length from end to end.

Chad

I need to drill/ream and tap it next.

I have a PM728VT mill that i plan to do those operations. With this pocket hole in the middle of the part. What is the best way to hold this part for drilling in the direction i need to go? I dont have a lathe.

I mean i can throw it in my 4" vise with the part sticking up. If you think that is all i need i will continue. It is just a lot of part sticking up and a long hole to drill.

3inch total length from end to end.

Chad