- Joined

- Feb 28, 2019

- Messages

- 499

Success!

Fortunately the arbor, at least the bottom end of it wasn't hardened and I was able to turn enough away to remove the tip of the center. After that I re-drilled the center hole and was back in business. Switched to a live center to support the free end and didn't have any more problems after that.

Making the precise gage block for controlling tooth spacing with the carriage and carriage stop took me two attempts. I over shot the milling of it the first time and left enough that I could sneak up on it by lapping the second time.

Doing the blanks for the racks was also a learning experience. Supper glue as a work holding approach worked out really well once I got the hang of it. I also leaned that I may want to tram/adjust my mill in the near future. It's pretty close but out by maybe a .001 - .002. I checked when I first got it and at that time figured I'd be just as likely to make it worse if I messed with it. More questions about that later.

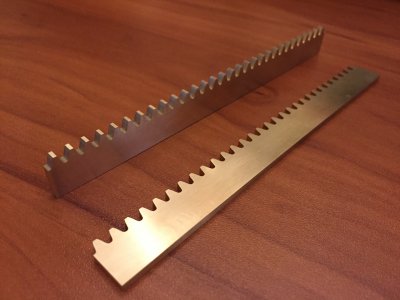

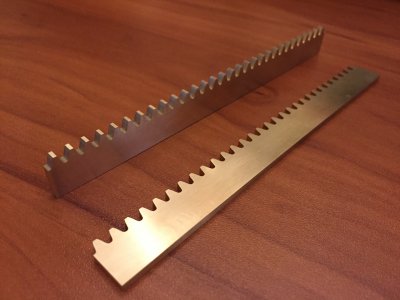

Here are two pic, the first is just the racks:

I spent some time working on surface finish - as I'm going to want to control that going forward and need to understand when and how to remove milling marks (could also work on better milled surface to begin with).

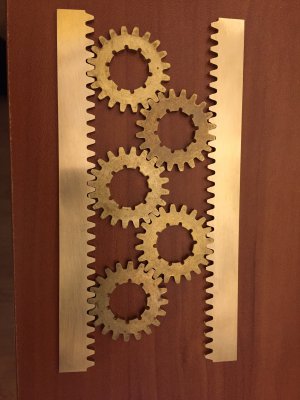

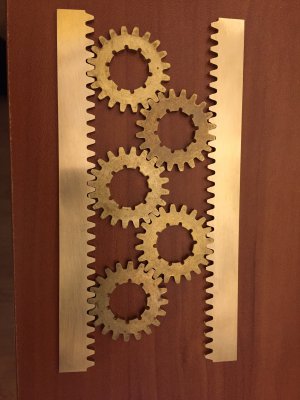

The second shot gives an idea where I'm going with this project. The racks and gears are going to be part of a locking box. Right now I'm just working through all the processes I'm going to need to master to bring this concept to fruition.

The gears will have splines in them. These gears have the splines roughed with a 1/16" end mill. Next task is to make a broach to square the bottoms of them.

I'm really psyched that this is starting to come together. Lots more to figure out and learn. The parts shown here are likely just trials - proving I can make the parts.

Thanks again for all the help.

-Dave

Fortunately the arbor, at least the bottom end of it wasn't hardened and I was able to turn enough away to remove the tip of the center. After that I re-drilled the center hole and was back in business. Switched to a live center to support the free end and didn't have any more problems after that.

Making the precise gage block for controlling tooth spacing with the carriage and carriage stop took me two attempts. I over shot the milling of it the first time and left enough that I could sneak up on it by lapping the second time.

Doing the blanks for the racks was also a learning experience. Supper glue as a work holding approach worked out really well once I got the hang of it. I also leaned that I may want to tram/adjust my mill in the near future. It's pretty close but out by maybe a .001 - .002. I checked when I first got it and at that time figured I'd be just as likely to make it worse if I messed with it. More questions about that later.

Here are two pic, the first is just the racks:

I spent some time working on surface finish - as I'm going to want to control that going forward and need to understand when and how to remove milling marks (could also work on better milled surface to begin with).

The second shot gives an idea where I'm going with this project. The racks and gears are going to be part of a locking box. Right now I'm just working through all the processes I'm going to need to master to bring this concept to fruition.

The gears will have splines in them. These gears have the splines roughed with a 1/16" end mill. Next task is to make a broach to square the bottoms of them.

I'm really psyched that this is starting to come together. Lots more to figure out and learn. The parts shown here are likely just trials - proving I can make the parts.

Thanks again for all the help.

-Dave