- Joined

- Nov 24, 2013

- Messages

- 254

I’m learning to make my own cutting tools for my Taig lathe and I bought a few HSS blanks 1/4" SQ x 2.5” long from KBC Tools in Toronto. I used a mild steel 1/4" SQ bar to practice the angles for a Face / Turning tool and I’m happy with the results (I follow a thread shown the process in details)

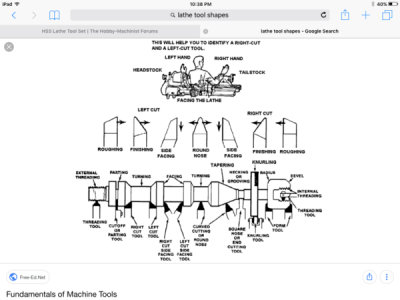

However my problem as a beginner is how to know which tool is required for a certain cut and what the angles / shapes are for each tool. The thread I follow is only for a face / Turning tool.

Is there somewhere a guide showing the tool required for certain cuts including picture of the tool?

Thanks

However my problem as a beginner is how to know which tool is required for a certain cut and what the angles / shapes are for each tool. The thread I follow is only for a face / Turning tool.

Is there somewhere a guide showing the tool required for certain cuts including picture of the tool?

Thanks