- Joined

- Nov 9, 2013

- Messages

- 146

I have been working on a variety of other projects so my hydra shift 15 has been languishing in the corner unloved.

I never could get it to cut properly, and it had issues. The crossfeed was difficult to turn and it had half turn of endplay. Disassembly revealed a bent screw and that all the components between the nut and the end of the screw are missing.

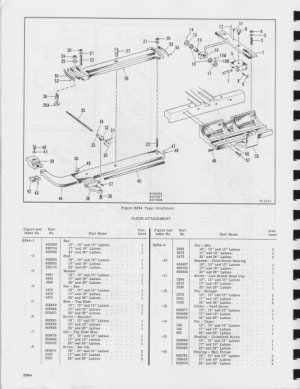

Looking at the parts book, It's not immediately obvious how the missing collar, bushing and bearing are supposed to be held in place. Just to complicate it a bit further, the machine came with parts of the taper but not all of it.

I would appreciate any advise, pics or help of any kind.

hh

I never could get it to cut properly, and it had issues. The crossfeed was difficult to turn and it had half turn of endplay. Disassembly revealed a bent screw and that all the components between the nut and the end of the screw are missing.

Looking at the parts book, It's not immediately obvious how the missing collar, bushing and bearing are supposed to be held in place. Just to complicate it a bit further, the machine came with parts of the taper but not all of it.

I would appreciate any advise, pics or help of any kind.

hh