Hi all,

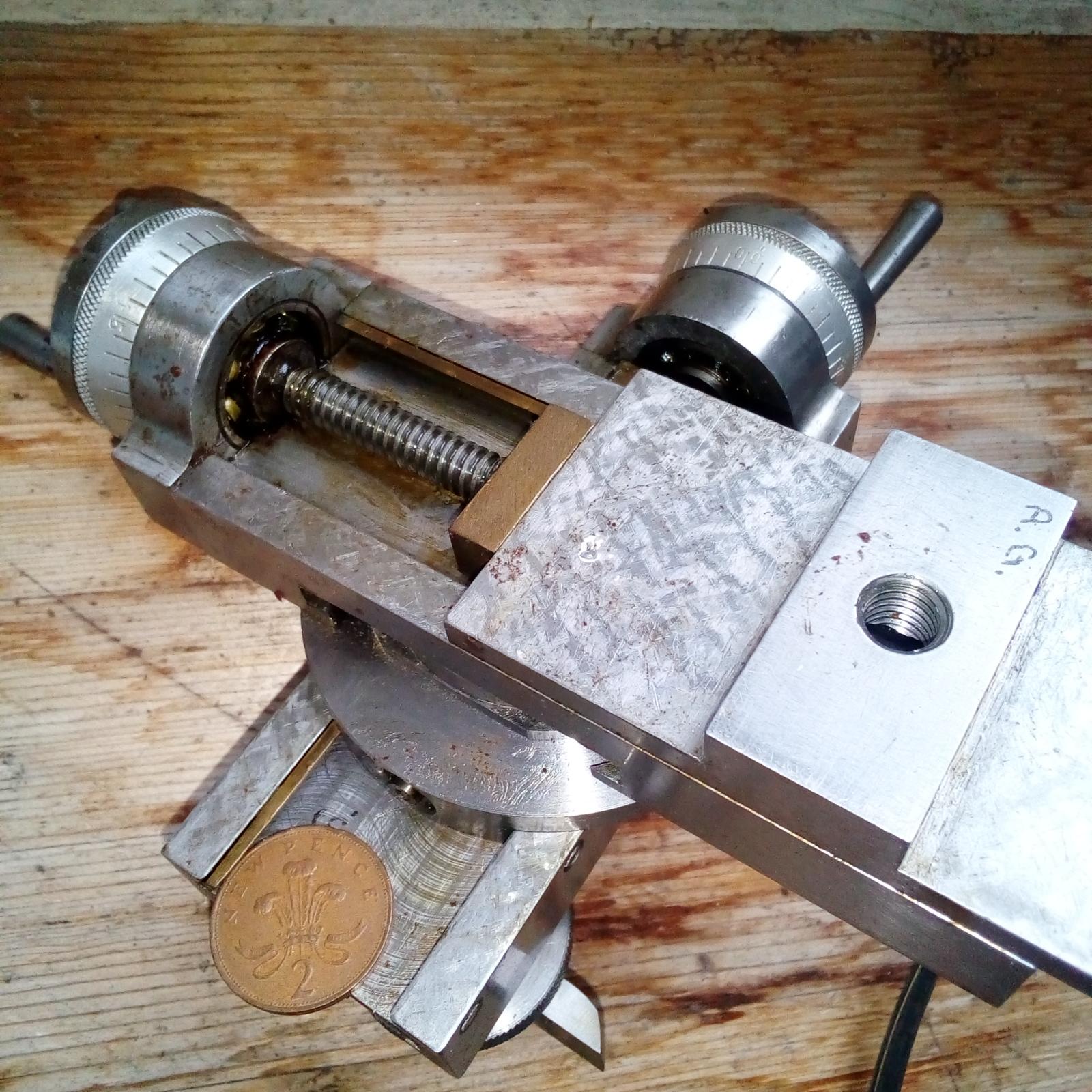

as per title, I bought this very nice little bench lathe. It was not used at all, looks and feel very nice. I measured the spindle runout and it's a 1 micron or less.

Bought it in Switzerland, it uses W20 Schaublin type collets. Does anybody recognize the maker of this lathe?

Thanks

as per title, I bought this very nice little bench lathe. It was not used at all, looks and feel very nice. I measured the spindle runout and it's a 1 micron or less.

Bought it in Switzerland, it uses W20 Schaublin type collets. Does anybody recognize the maker of this lathe?

Thanks