- Joined

- Feb 24, 2019

- Messages

- 924

A few years ago I thought I had bought the greatest bang for my buck machine. It had a good legacy, etc.

A Smithy Midas 3 in 1 machine.

Well, they are now discontinued. Just my luck.

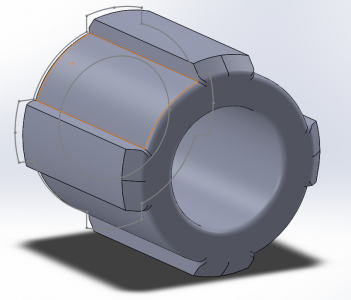

In the gearbox, there are a couple sacrificial parts.

Here's what happened and happened again.

While using the power feed, I locked my X-axis and was using power feed on the Y-axis, I accidentally threw the lever from Y to X and the sacrificial part broke, again.

The problem is, the replacement part has been discontinued as well. Last time I ordered a replacement part was about 4 years ago and I was smart enough to buy two of them but it's the wrong length since a different part broke this time. First thing I'm thinking of doing is to to cut down the part I have but if the longer one in my machine breaks again I'd be back at square one.

So, does anyone know of a compatible replacement?

I'm in the process of adding a stepper driven power feed so, theoretically, in a couple months I won't need this gear other than for threading (which I've only done on this machine once in the years I've owned it).

Another alternative would be for me to make "something that will work" out of brass or aluminum.

A Smithy Midas 3 in 1 machine.

Well, they are now discontinued. Just my luck.

In the gearbox, there are a couple sacrificial parts.

Here's what happened and happened again.

While using the power feed, I locked my X-axis and was using power feed on the Y-axis, I accidentally threw the lever from Y to X and the sacrificial part broke, again.

The problem is, the replacement part has been discontinued as well. Last time I ordered a replacement part was about 4 years ago and I was smart enough to buy two of them but it's the wrong length since a different part broke this time. First thing I'm thinking of doing is to to cut down the part I have but if the longer one in my machine breaks again I'd be back at square one.

So, does anyone know of a compatible replacement?

I'm in the process of adding a stepper driven power feed so, theoretically, in a couple months I won't need this gear other than for threading (which I've only done on this machine once in the years I've owned it).

Another alternative would be for me to make "something that will work" out of brass or aluminum.