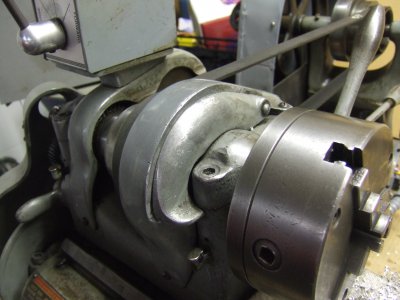

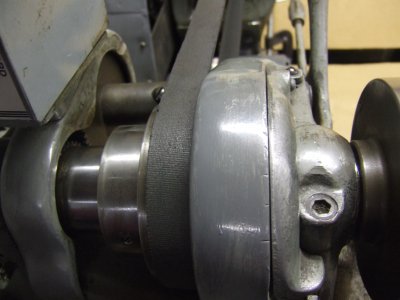

Man oh Man, I believe I just sheared the key that couples the spindle pulley to the spindle! I was using my milling attachment using a 3/8ths endmill on an aluminum round late last night when I noticed the tool slow quickly and then stop turning while the pulley continues to turn. I withdrew the tool and I could spin the chuck independent of the running motor/pulley. I've never taken this lathe apart before as it is new to me but it must be similar in its coupling between the two driven parts of an Atlas 12" I've had long ago. For all I know, I may have stripped the pulley keyway itself, or God forbid, the spindle keyway. I don't imagine it could be something else wrong but I might be missing something. I will have to get it apart to know for sure. Anyone have this happen to their Southbend 9"?

Any precautions, tips and tricks, suggestions on dismantling the headstock spindle assembly so that I could do this repair smoothly and not mess it up? Looking at it, it seems fairly straightforward but I am not yet familiar with the nuances of this lathe's construction. I know, I should get a new flat belt while I'm at it. Suggest what is a better brand of flat belt and where to get one? Anything else I should service while it is being taken apart anyway? Thanks for your input.

By the way, I was making a part for my lathe keyway slotter project when this happened. Another project on hold now.

Any precautions, tips and tricks, suggestions on dismantling the headstock spindle assembly so that I could do this repair smoothly and not mess it up? Looking at it, it seems fairly straightforward but I am not yet familiar with the nuances of this lathe's construction. I know, I should get a new flat belt while I'm at it. Suggest what is a better brand of flat belt and where to get one? Anything else I should service while it is being taken apart anyway? Thanks for your input.

By the way, I was making a part for my lathe keyway slotter project when this happened. Another project on hold now.