I'm still really green to machining as most my career I was a car mechanic. I did a lot of engine rebuilding and used mic's and DI's and other gages. But the old stuff like what you have I'd never seen till the Steam Powered Machine Shop. There are several antique stores and every once in a while an estate sale and more often than not I'm totally stumped by some tool. Maybe somebody like Mr.Pete could have your indicator on his channel and somebody could chime in who made it and how it was used. I have a tendency to think things would have been crudely made back then, but then I find something like this Darling, Brown &Sharpe angle gage. It was a somewhat pitted, but it works perfectly and smoothly. Check out the date, and I'd never seen Darling, Brown & Sharpe, just Brown & Sharpe. How'd they do that?

I have seen those of various periods on ebay. As for yours, patent 1887, Mr. Darling joined Brown and Sharpe and then left so that also dates your protractor. I saved the history to wordpad and I will paste it here.....

FROM WIKIPEDIA

""Brown & Sharpe was founded in 1833 on South Main Street[3] in Providence, Rhode Island by David Brown and his son Joseph R. Brown. The elder Brown retired in 1841, and the younger Brown formed a partnership with Lucian Sharpe in 1853, giving the company its name.

The early years were full of innovations and inventions, including the first automatic machine for graduating rules (1850) and the precision Gear Cutting and Dividing Engine (1855).[3]

The company was incorporated in 1868. In 1866 Samuel Darling joined the partnership and the firm changed its name to Darling, Brown and Sharpe until Darling's interest was bought out in 1892.""

So DB&S or Darling Brown and Sharpe markings are from 1866 to 1892. And with a patent date 1887 (I can't read the other pat date) that narrows your protractor down to 1887-1892 unless they continued to stamp the name after Darling left. I have a couple of DB&S machinists squares. Also according to the history if a piece is marked J R BROWN AND SHARPE it is 1853 - 1866. There was a center finder on ebay J R Brown and Sharpe but I was outbid at 124.00 when I tried to snipe it. I do have a later center finder square just like it with B&S which would be post 1892, see photo.

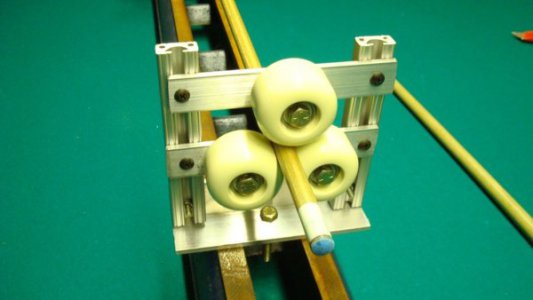

I too am relatively green at machining. I worked as an auto mechanic during summer between college sessions because I did that kind of work as a poor boy necessity just to keep a car under me that I could afford. After college and military service I ended up being an electrician simply because I got a decent job in it and though mostly self taught combined with OJT I was able to fix stuff at a mill and it paid the family well. I have only been machining about 5 years and mostly limited to cues and making what I need for that. Since I am walking disabled it is a great enjoyment to me. I can walk with a cane a few feet but must sit soon or fall. I use a rollator to shoot pool, that is how much I love the game.