- Joined

- May 15, 2017

- Messages

- 12

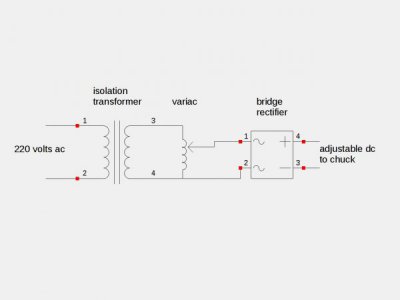

So I have an old walker 220-240v chuck, no idea how old it is and walker refuses to respond to my multiple emails asking about it. Its mounted to an old Norton surface grinder from the 40s. The original power supply was spliced off the motors 3ph 240v and goes into two large tube rectifiers and a large isolation transformer. None of the old tech works anymore. The isolation transformer is fried as are the 2 tubes. I just want a way to wire this up to its own power or from the machines power, I just want it to work. I went to my friend who is an electrical engineer and he told me Id need an isolation transformer so I dont get shocked and apparently a 1:1 240v isolation transformer is hard to find and very expensive... I was wondering if you guys knew any other way to wire these things