- Joined

- Aug 3, 2015

- Messages

- 154

ARRRRGGGG! Ratsafratsin off-brand second-rate imitation of a tool!

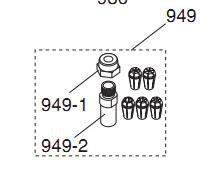

The draw-in bar pulls the whole collet holder into the quill on the G0516.

The collet holder setup on this thing is an oversized copy of a stinkin' Dremel. The part I hadn't torque-up properly was the 'retaining nut'.

More egg on the face for the n00b.

I googled how REAL milling machines are built. I saw how the draw bar tightens the collet in those.

The draw-in bar pulls the whole collet holder into the quill on the G0516.

The collet holder setup on this thing is an oversized copy of a stinkin' Dremel. The part I hadn't torque-up properly was the 'retaining nut'.

More egg on the face for the n00b.

I googled how REAL milling machines are built. I saw how the draw bar tightens the collet in those.