The bug issue with the solid carbide boring bars is they have ZERO forgiveness. All you will hear is a "tink", and you will now have a 2 piece bar.

Hey Joe, I've heard that "tink"! I gave up a very expensive Kennametal boring bar and it was all due to my own stupidity. I used it in a tool holder that used set screws to lock the bar in the holder. Snapped it right in half. I've had pro machinists tell me that they never snapped a carbide bar like that and that I was wrong - maybe, but when I spoke to a Kennametal rep on the phone he laughed and said it happens far more often than you might think. Always best to use a circumferential holder like an Aloris 4D with these bars.

Man o man, I must be very lucky!

I have yet to hear that "tick". Well I have heard the tick from breaking carbide inserts & end mills but never on any of my solid carbide boring bars, not even a chip.

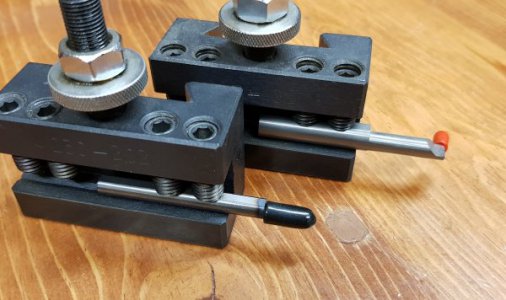

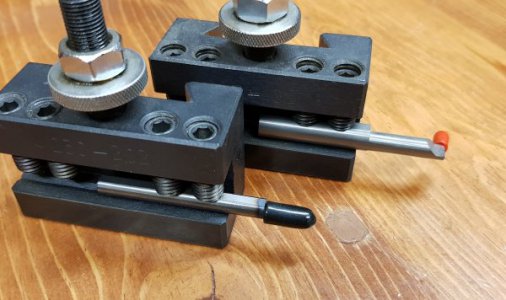

Maybe my luck is purely coincidental? On my import holders, like many, I change out the set screws before even using them but for two reasons. Second reason, the tools are hard, I don't like (or see a need) cut point set screws trying to dig into my tool shanks so I use flat tip set screws for all my tools. My Dorian holders came with cup point set screws but they don't have sharp cups, they're smoothened over. Still I machined them flat anyway.

Also when I tighten down my tools, I use a t-handle hex & just snug them, no gorilla tightening (not needed IMO), and the hex shank on my t-handles will twist under load anyway. I also start with the two inner set screws first, then snug up the outer two, then follow up again on all four.

Maybe this is a why I have never broken any carbide boring bars? Never even broken any of my small Micro100 carbide bars either. The faint set screw marks on my boring bars prove that I adjust them often. Been using them like this from day one & never had a problem.