I've had my Aloris BXA rotate on me when taking heavy cuts and/or parting. I've not yet made a solid plinth for lathe( Summit 1440B ), though I will. In the mean time, I thought I'd try to make a beefier T-nut than the relatively thin piece of stock that Aloris supplies with the tool post. I had a feeling there was some flexing going on, which allowed the slippage. Also used this project as an opportunity for some more surface grinder practice. The degree of precision taken wasn't necessary, this was all due to the grinder practice.

After making a basic sketch in Fusion 360, a piece of 4140 Normalized was squared up in the mill, and then ground to the final dimension of the basic block needed to make the part.

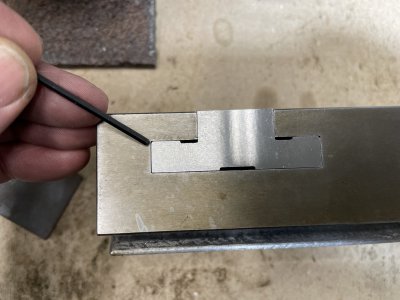

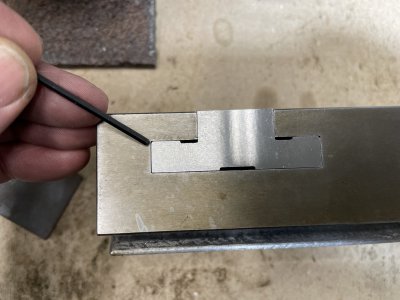

Then the "ears" were machined away, and then reliefs were made with a corner radius end mill in the inside corners of the "T". This is intended to move the load further back into the corner where the nut has less leverage on the compound. Another relieff was cut down the center of the bottom face, to make clearance for potential dimples formed by the two set screws. Will be using brass tipped screws, so this is just in case. Then the outside corners were chamfered for corner clearance when the set screws and tool post are tightened.

The final part, and the stripped down compound, ready for reassembly.

Back on the lathe. A small plastic plug for the exposed set screw hole. As soon as I put the hold down nut on the tool post, it was apparent that this was going to be a good thing. After putting the nut on hand tight, I could only get another 1/4 turn or so with a wrench to full tight. It just had that feel when you have close fitting rigid parts, and when tightening them down the nut/bolt just comes to a sudden and abrupt stop. Looking forward to taking some test cuts, but it will have to wait for a couple of weeks. Have little doubt that it will work very well.

After making a basic sketch in Fusion 360, a piece of 4140 Normalized was squared up in the mill, and then ground to the final dimension of the basic block needed to make the part.

Then the "ears" were machined away, and then reliefs were made with a corner radius end mill in the inside corners of the "T". This is intended to move the load further back into the corner where the nut has less leverage on the compound. Another relieff was cut down the center of the bottom face, to make clearance for potential dimples formed by the two set screws. Will be using brass tipped screws, so this is just in case. Then the outside corners were chamfered for corner clearance when the set screws and tool post are tightened.

The final part, and the stripped down compound, ready for reassembly.

Back on the lathe. A small plastic plug for the exposed set screw hole. As soon as I put the hold down nut on the tool post, it was apparent that this was going to be a good thing. After putting the nut on hand tight, I could only get another 1/4 turn or so with a wrench to full tight. It just had that feel when you have close fitting rigid parts, and when tightening them down the nut/bolt just comes to a sudden and abrupt stop. Looking forward to taking some test cuts, but it will have to wait for a couple of weeks. Have little doubt that it will work very well.