- Joined

- Dec 1, 2010

- Messages

- 1,172

Re: In search of a good Steady Rest

This should be a great build, and of interest to many members here. Seems so many lathes get passed around, and dont have the steady, or as in Bill,s case, not big enough to do the job.

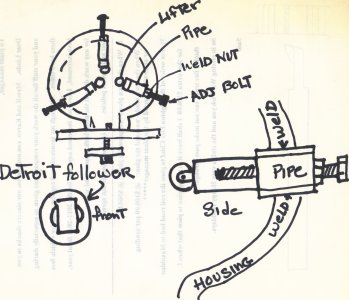

I looked over the drawing, and I think it will be a nice piece when Bill gets it done. Being that its been decided by Bill to make the steady now, because it is needed for his other project, and post the build up of this project will have many of the members watching the progress.

I can say that from the drawing, this isnt going to be a run of the mill quick and dirty build. Im sure this steady will be of the best quality. Now its been started, keep yer eyes peeled, the good stuff is yet to come

This should be a great build, and of interest to many members here. Seems so many lathes get passed around, and dont have the steady, or as in Bill,s case, not big enough to do the job.

I looked over the drawing, and I think it will be a nice piece when Bill gets it done. Being that its been decided by Bill to make the steady now, because it is needed for his other project, and post the build up of this project will have many of the members watching the progress.

I can say that from the drawing, this isnt going to be a run of the mill quick and dirty build. Im sure this steady will be of the best quality. Now its been started, keep yer eyes peeled, the good stuff is yet to come