Recently found a great deal on a Swiss made Fisso flexible arm( think Noga on steroids ) indicator stand on eBay. It had suction cup base on it, so it went in the drawer for other things, and set to making a proper base for it.

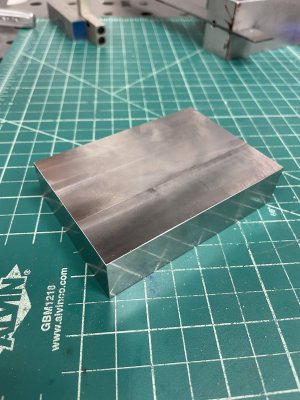

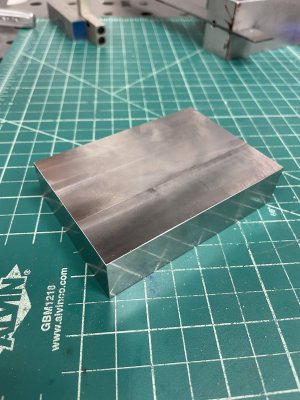

Squared up a leftover chunk of Dura-Bar that was just about the right size. Since the Fisso arm is metric, the base was done to metric dimensions as well. 100mm x 70mm x 25mm.

Then added scallops in the sides, to make it easier to hold on to.

Drilled & tapped the top for the M8-1.25 stud on the flex arm, and drilled reamed four 3/8" holes in the bottom for carbide feet( the only non-metric components ) Before pressing in the carbide feet, I used the rear to holes to act as a pivot guide to round the corners on the belt grinder. Will leave the front surface flat/square, as I may eventually add a radiused projection, so it can pull double duty as a squareness comparator. Used Oxpho-Blue to cold blue the base, and pressed in the feet. Still need to surface grind them to a common plane, but that will have to wait. Rearranging the shop a bit, and want to wait until the surface grinder is relocated and leveled. Should work great, and be much more repeatable when using a tenths indicator, compared to a Noga. The adjustment mechanism in the Fisso is far superior, and it's just more robust in every way.

Squared up a leftover chunk of Dura-Bar that was just about the right size. Since the Fisso arm is metric, the base was done to metric dimensions as well. 100mm x 70mm x 25mm.

Then added scallops in the sides, to make it easier to hold on to.

Drilled & tapped the top for the M8-1.25 stud on the flex arm, and drilled reamed four 3/8" holes in the bottom for carbide feet( the only non-metric components ) Before pressing in the carbide feet, I used the rear to holes to act as a pivot guide to round the corners on the belt grinder. Will leave the front surface flat/square, as I may eventually add a radiused projection, so it can pull double duty as a squareness comparator. Used Oxpho-Blue to cold blue the base, and pressed in the feet. Still need to surface grind them to a common plane, but that will have to wait. Rearranging the shop a bit, and want to wait until the surface grinder is relocated and leveled. Should work great, and be much more repeatable when using a tenths indicator, compared to a Noga. The adjustment mechanism in the Fisso is far superior, and it's just more robust in every way.