- Joined

- May 4, 2019

- Messages

- 792

I rarely use insert tooling for parting, except on hardened steel. I trashed too many holders due to chip jamming. HSS works just fine for most things.

I rarely use insert tooling for parting, except on hardened steel. I trashed too many holders due to chip jamming. HSS works just fine for most things.

www.hobby-machinist.com

www.hobby-machinist.com

I think, a stick out of 50 mm is way beyond the limits (regidity) of a (your) lathe.

I have mounted the tool (1" parting blade, SP200 insert) upside down, alway use power feed, always use lubrication, do it in one pass and find aluminum more challenging than steel. For me the limit is 50 mm diameter (25 mm stickout). Beyond that, I use a band saw.

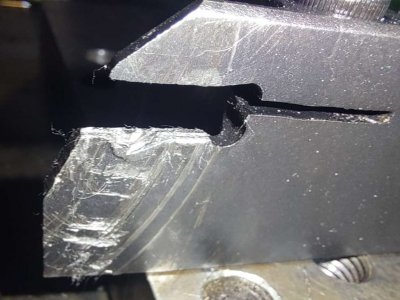

What is the maximum stickout/diameter you would feel comfortable parting with it?View attachment 439717This is the type of parting blade holder use.

Thanks. I've read it previously, but I haven't followed it... I had problems with hss, but then I had (limited) success with insert holder. I'll give hss another go next time I have to part stuff.You might find this helpful:

Parting Operations on the Lathe - Lessons Learned & Best Practices

When I was first getting started, parting operations were absolutely the most challenging and frustrating aspects of lathe use. So, I decided to document what I learned in my quest to overcome my fear, uncertainty, and doubts on the topic, and attain reasonable proficiency in parting operations...www.hobby-machinist.com