- Joined

- Jul 6, 2022

- Messages

- 171

I finally installed the quick change tool post. It was not an easy install however.

When I removed the 4 way tool post I was expecting that the stud was screwed in, and I could just unscrew it and somehow machine the stud for the QCTP to fit the lathe. Except the stud is somehow firmly stuck to the compound and no amount of unscrewing would get it loose. I even looked at Abom's video on youtube to see if he has any input for installing a quick change tool post to a Victor lathe (his already has a multifix tool post installed) but I couldn't find any such video. Guess the lathe was given to him with the multifix tool post installed.

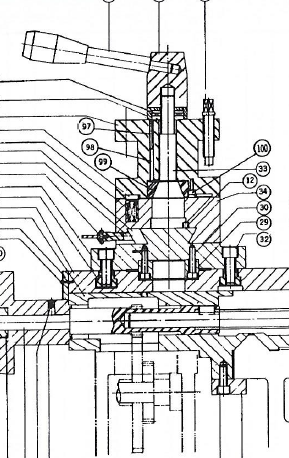

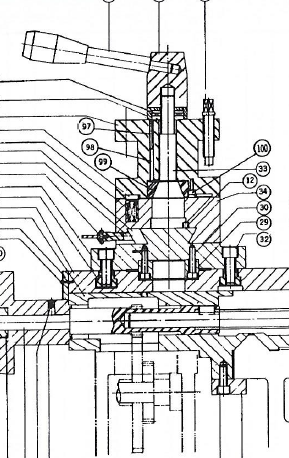

So I looked at the parts diagram for the victor lathe and this is how my lathe's tool post stud is installed:

I'm sorry I don't have a picture, but essentially the stud is a one piece of metal that is pressed into the compound (part #33), and secured with a set screw.

What I had to do is take the entire compound apart, then back out the set screw, pound the stud out from under the compound. After the stud comes off I must then cut the stud off, drill a hole and tap it to fit the CXA tool post stud (it's 3/4" - 16 TPI). Then I have to pound that assembly back into the compound, replace the set screw, then put the whole compound together.

The piece of metal on the compound is going to be machined into a tool holder.

I really envy those lathes that have a T slot on the compound rather than this... but I never seen a lathe with a T slot. The piece that comes with the tool post is intended so that you can machine it to fit whatever T slot your lathe has... if it was that easy...

When I removed the 4 way tool post I was expecting that the stud was screwed in, and I could just unscrew it and somehow machine the stud for the QCTP to fit the lathe. Except the stud is somehow firmly stuck to the compound and no amount of unscrewing would get it loose. I even looked at Abom's video on youtube to see if he has any input for installing a quick change tool post to a Victor lathe (his already has a multifix tool post installed) but I couldn't find any such video. Guess the lathe was given to him with the multifix tool post installed.

So I looked at the parts diagram for the victor lathe and this is how my lathe's tool post stud is installed:

I'm sorry I don't have a picture, but essentially the stud is a one piece of metal that is pressed into the compound (part #33), and secured with a set screw.

What I had to do is take the entire compound apart, then back out the set screw, pound the stud out from under the compound. After the stud comes off I must then cut the stud off, drill a hole and tap it to fit the CXA tool post stud (it's 3/4" - 16 TPI). Then I have to pound that assembly back into the compound, replace the set screw, then put the whole compound together.

The piece of metal on the compound is going to be machined into a tool holder.

I really envy those lathes that have a T slot on the compound rather than this... but I never seen a lathe with a T slot. The piece that comes with the tool post is intended so that you can machine it to fit whatever T slot your lathe has... if it was that easy...