- Joined

- Feb 5, 2014

- Messages

- 198

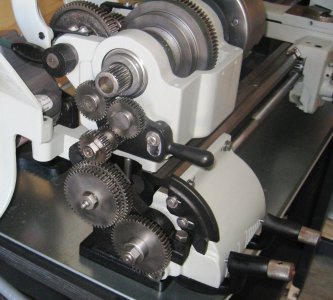

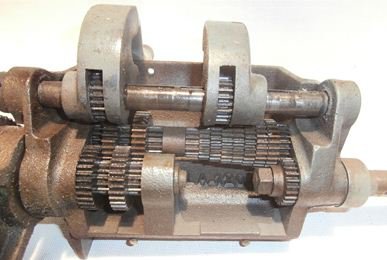

I have always avoided the change gears on my lathe. It is just a pain to do for a lathe that really does not get alot of use but is very useful when i need it. I have always wanted to install a QCGB on it. This is my thread to do so.

The game plan is:

- Research, research, research.

I have yet to find this conversion done but i have read a few items in adapting QCGB's to larger Logans.

- Locate a suitable gearbox.

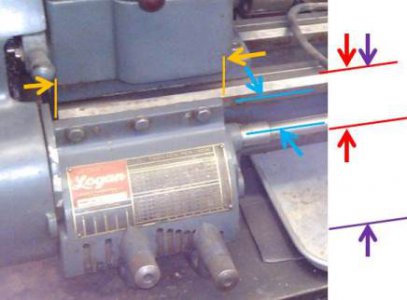

From a 9B if possible but rumor has it that the 10" and 11" Logan's are the same.

- Figure out what, if anything needs to change or be added for the adaptation.

I do not expect it to just bolt up.

- Get-er-done.

I have owned my Logan 400 for about 20 years. (The logan 400 is a 9", short bed lathe. It is VERY similar to the Logan 1400 and 9B) It was made in the late 40's. My Grandfather bought it in the 50's or 60's from a VW shop that used it to turn brake drums. It was passed down to me.

Over the last 6 weeks i have undertaken a full restoration of the lathe once i found that the headstock bearings were shot. That project can be seen here.

http://www.hobby-machinist.com/showthread.php?t=20631

The restoration is not yet complete but i am too the point where i am slowing down as i wait for the last few bits to arrive.

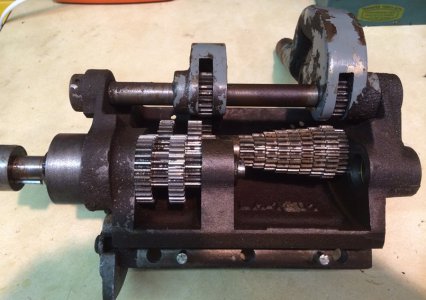

In all honesty, i am already nearly complete with the first step and i have already located and secured the a QCGB from a 9B. However, for posterity and to help the next guy who wants to do this i will step thru each part with what i have learned and done. I believe this thread would also be helpful for anyone with a larger or different model Logan who wants to do the same.

Matthew

The game plan is:

- Research, research, research.

I have yet to find this conversion done but i have read a few items in adapting QCGB's to larger Logans.

- Locate a suitable gearbox.

From a 9B if possible but rumor has it that the 10" and 11" Logan's are the same.

- Figure out what, if anything needs to change or be added for the adaptation.

I do not expect it to just bolt up.

- Get-er-done.

I have owned my Logan 400 for about 20 years. (The logan 400 is a 9", short bed lathe. It is VERY similar to the Logan 1400 and 9B) It was made in the late 40's. My Grandfather bought it in the 50's or 60's from a VW shop that used it to turn brake drums. It was passed down to me.

Over the last 6 weeks i have undertaken a full restoration of the lathe once i found that the headstock bearings were shot. That project can be seen here.

http://www.hobby-machinist.com/showthread.php?t=20631

The restoration is not yet complete but i am too the point where i am slowing down as i wait for the last few bits to arrive.

In all honesty, i am already nearly complete with the first step and i have already located and secured the a QCGB from a 9B. However, for posterity and to help the next guy who wants to do this i will step thru each part with what i have learned and done. I believe this thread would also be helpful for anyone with a larger or different model Logan who wants to do the same.

Matthew