- Joined

- Nov 2, 2019

- Messages

- 8

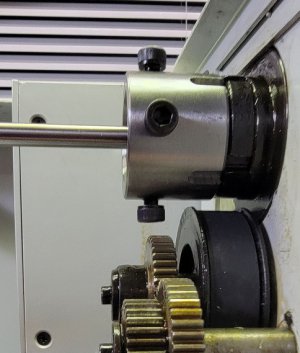

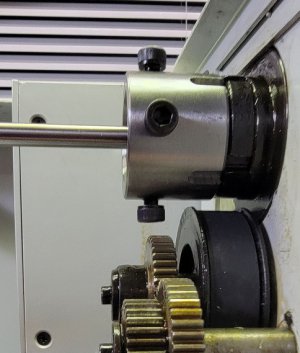

I needed a spider for my SIEG SC4 (LMS 3540) lathe. It turns out the classic mini-lathe spindle terminates with the same thread, and so the LMS mini-lathe spider fits on nicely. Clearance from the spider body to the SC4's default 41 toothed gear is 13 mm, and the picture shows what the clearance looks like while holding 5/16" drill rod. If I add two other sets of cap head screws (1 set 0f 15 mm and one set of 10 mm) to complement the 20 mm ones that are part of the kit, I should be able to support anything up to the 20 mm max capacity of the spindle bore while keeping clearance. Perfect? No... But it is a serviceable alternative until I have time to make something a little nicer...

Last edited: