The LMS 8.5" is in a completely different class than other common lathes of that general size, it is not the usual cheap "mini-lathe". It also costs double the price of most other 8" and 9" lathes. The PM1022 is probably the only easily available lathe of roughly similar size that really compares well to it.

The 8.5" has more features than the Grizzly 9x19 and 10x22 lathes, primarily the inclusion of a power cross feed. It is also only 1" difference in swing. Most of the 10x22 are actually 9.5" swing.

PM1022 is not really much more expensive new, $2700 for the LMS 7500, vs $2900 for the PM1022. $2000 for that lathe is probably a fair price, as with that tooling, stand etc you are probably closer to $3400 to buy new.

The 7500 can actually cut a few more threads 6-80 / .25-4.0 than the PM1022 8-80 / .35-3.0

Both are variable speed but the PM1022 has a slightly lower speed range 50-2000 vs 100-2000 on the 7500

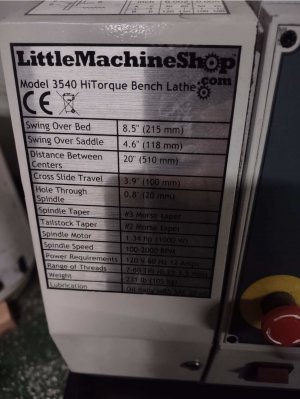

Of course the PM1022 is a little larger with a 10" swing, 22 or 30" between centers, and a 1" spindle bore vs 8.5x20" and a 0.8" spindle bore.

PM1022 can be assumed to be more rigid, as it weighs 50% more 340lbs vs 220lbs. The 1022 is only 4" longer and both machines are similar depth so you are not saving a huge amount of space going with the 8.5".

Anyway, I think that is a fair price for the lathe and for the size it is a pretty capable machine (on paper anyway). Buying new, I agree with the other posters that I'd probably go with the PM1022 as you are getting a little more for similar cost.

However for $2000 for that lathe which you can go and pick up vs a similarly equipped new PM1022 at $3200 (with stand) + $250 shipping and taxes, I'd take a good look at it, it is nearly 1/2 what you will pay for a new PM1022. I have no idea what your plans are though, it is quite possible that even the 1022 is not enough lathe for you, or either could be more than enough. Both are quality small import lathes.

I have no connection to PM or LMS, just a nerd for small lathes and I like digging into the details. Both companies have a solid reputation for good customer service. I've spent a lot of money with LMS for tooling (no machines) and have zero complaints.

Before I spent $2K on a used 8.5" lathe that requires change gears I'd take a hard look at a Precision Matthews PM-1022V which has a gearbox and a larger spindle bore (1" versus .8"). Yes, the LMS machine has 1.3hp instead of 1hp, but I don't believe you can use all that power on an 8.5" machine that weighs 225lbs. I just sold a 13x36" Sheldon lathe that weighed 1,400lbs and it only had 1hp...it was more than enough. You'd also get a warranty with a new machine. The PM comes with most of what seems to be included with the used LMS machine. Granted, you're talking $3K total versus $2K, but getting a more capable machine, and a warranty.

The PM lathes under 12" swing also require change gears. They do have a gear box but it is for the power feed speeds, not threading, although they will do a handful of threads per gear set. Same with the 9x20 and Grizzly 10x22 lathes. The gear box throws people, but they are not a full range threading QCGB like on larger lathes or many vintage lathes.