- Joined

- Sep 28, 2013

- Messages

- 4,318

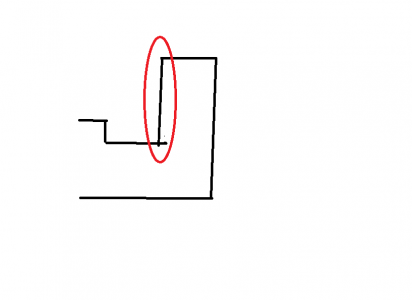

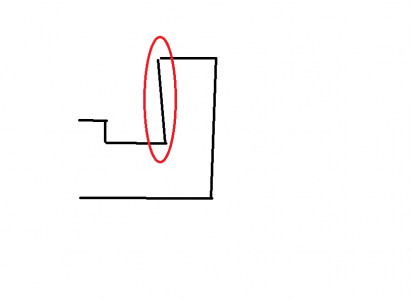

you're welcome Terry  Not to be difficult, but it matters where the clearance is - there may be lots of clearance on the tool as a hole, so only the cutting edge touches the material. What I'm talking about is clearance once the cutting edge is in the material - think of a parting blade, the sides have to be perpendicular to the cutting edge or less (the cutting edge has to be wider than the rest of the blade) or the side will start cutting too. More cutting edges (or a larger one) = more force to cut = more potential for chatter. I have a pic somewhere..

Not to be difficult, but it matters where the clearance is - there may be lots of clearance on the tool as a hole, so only the cutting edge touches the material. What I'm talking about is clearance once the cutting edge is in the material - think of a parting blade, the sides have to be perpendicular to the cutting edge or less (the cutting edge has to be wider than the rest of the blade) or the side will start cutting too. More cutting edges (or a larger one) = more force to cut = more potential for chatter. I have a pic somewhere..

here you go, used it to cut the threading relief on a collet chuck - lots of stick out so I had some chatter, but it got the job done

see how the cutter narrows down on both sides going back from the cutting edge? That's the clearance I'm talking about.

here you go, used it to cut the threading relief on a collet chuck - lots of stick out so I had some chatter, but it got the job done

see how the cutter narrows down on both sides going back from the cutting edge? That's the clearance I'm talking about.