For some months, I wrote with numerous issues about threading on my Logan 820. Did a fair amount of restoring the machine, with help replaced the halfnuts, and now it's working like a charm; I've been regularly turning 48tpi with no issues.

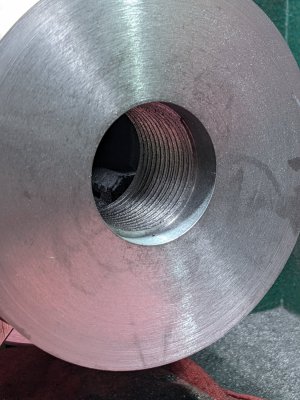

Now I'm on to more subtle stuff. The title names it: My Logan has a screw-on chuck and does not have a hard stop. I'm internal threading, on soft material, mostly ebonite and acrylic, always close to the chuck. When close to the chuck I usually use a Beall collet chuck and ER32. The threading works wonderfully on a through hole but I can't figure out how best to do it in a blind hole. With thanks to all the Youtube video creators and the answers I could find here, the only one I saw that did NOT say "don't do this if you have a threaded chuck" was Tom Griffin, of Tom's Techniques. Tom's method is to turn the compound around to 30 degrees from pointing away, then working forward. It seems to make sense, except for measuring a 5 thou cut from a dial across the ways, which in my setup is really clunky.

Does this method make sense to those with far more experience?

Many thanks,

Tim

Now I'm on to more subtle stuff. The title names it: My Logan has a screw-on chuck and does not have a hard stop. I'm internal threading, on soft material, mostly ebonite and acrylic, always close to the chuck. When close to the chuck I usually use a Beall collet chuck and ER32. The threading works wonderfully on a through hole but I can't figure out how best to do it in a blind hole. With thanks to all the Youtube video creators and the answers I could find here, the only one I saw that did NOT say "don't do this if you have a threaded chuck" was Tom Griffin, of Tom's Techniques. Tom's method is to turn the compound around to 30 degrees from pointing away, then working forward. It seems to make sense, except for measuring a 5 thou cut from a dial across the ways, which in my setup is really clunky.

Does this method make sense to those with far more experience?

Many thanks,

Tim