- Joined

- Jan 15, 2016

- Messages

- 58

I'm going to try and learn how to weld. I'm setting up to do some small hobby welding projects. I need a way to cut material. Mostly small stuff. I'm not interested in an abrasive cut off saw.

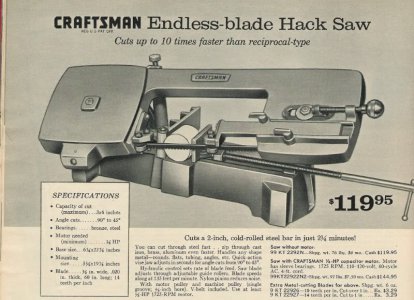

How would an old school cool vintage Craftsman saw compare to an Asian 4x6? Is the Craftsman capable of cutting just as straight?

Comparing the accuracy of the cuts between an old Craftsman, Asian 4x6, or a portable bandsaw on a stand, are any of them able to just cut and go with minimum dressing up and go weld?

Point is if each one would need trued up I do have an old Craftsman disc/belt combo sander I can drag out of the basement for the task. I was planning on putting it into service anyway. If I have to straighten up a crooked cut, maybe I should just pic the saw I like best and go with it?

I really like these old Craftsman's. Are they worth having? They are a bit smaller than the 4x6 and I might be able to sit one on my work bench. It would look good next to my old 1936 Walker Turner drill press.

Random pic of the saw I found on line. And my drill press just for cool factor,,,lol.

How would an old school cool vintage Craftsman saw compare to an Asian 4x6? Is the Craftsman capable of cutting just as straight?

Comparing the accuracy of the cuts between an old Craftsman, Asian 4x6, or a portable bandsaw on a stand, are any of them able to just cut and go with minimum dressing up and go weld?

Point is if each one would need trued up I do have an old Craftsman disc/belt combo sander I can drag out of the basement for the task. I was planning on putting it into service anyway. If I have to straighten up a crooked cut, maybe I should just pic the saw I like best and go with it?

I really like these old Craftsman's. Are they worth having? They are a bit smaller than the 4x6 and I might be able to sit one on my work bench. It would look good next to my old 1936 Walker Turner drill press.

Random pic of the saw I found on line. And my drill press just for cool factor,,,lol.