-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is there such a thing as an R8 collet block?

- Thread starter jmarkwolf

- Start date

Use your 5C collet block to make your own R8 collet block. Or just bite the bullet and buy more 5C collets. I just happen to have 4 duplicates I would like to sell. All 4 are Hardinge and are used. They are 1/8, 1/4, 1, and 1-1/16. $8 each plus shipping.

- Joined

- Feb 9, 2017

- Messages

- 5,247

I have wondered and asked that on different forums. I only found mention of it on Alibaba but couldn't seem to be able to order it. So it's down the list of todo's. Before that I want to make block for r8 that I can swap into my QCTP to do deep drilling on the lathe where my tail stock can't get in there.I have a 5C collet block which comes in handy sometimes, but I only have a couple collets.

I have a boatload of R8 collets.

An R8 collet block would be more practical for me, but I have not seen them.

- Joined

- Jun 7, 2013

- Messages

- 10,087

More handy and effective is a QCTP holder that is either made with a morse taper socket or one that mounts a drill chuck, which is better in some ways, since the overall length is shorter than the MT block when using a drill chuck in it.I have wondered and asked that on different forums. I only found mention of it on Alibaba but couldn't seem to be able to order it. So it's down the list of todo's. Before that I want to make block for r8 that I can swap into my QCTP to do deep drilling on the lathe where my tail stock can't get in there.

A disadvantage to using R8 is that they do not have the maximum capacity of the 5C, besides not having the pass through capability. Personally, I use collets very little, and only in square and hex blocks. Most such work is done in a dividing head with a 3 jaw chuck. Both my lathes came with collet attachments that took other, less popular collets, and a Jacobs collet outfit.

- Joined

- Nov 12, 2017

- Messages

- 391

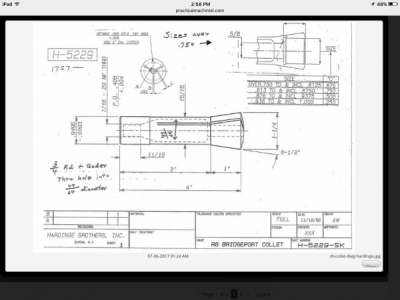

It only takes creativity; if you have a lathe and a mill, select decent material. I have a drawing with details sorted out.

It'll only cost you a PM.

Preceding considerations offered are valid; but neglect fact building up a shop is only linear with serious resources. Awhile later you'll buy 5C's like everyone else does; but won't/ can't claim they know about making operative blocks.

It'll only cost you a PM.

Preceding considerations offered are valid; but neglect fact building up a shop is only linear with serious resources. Awhile later you'll buy 5C's like everyone else does; but won't/ can't claim they know about making operative blocks.

- Joined

- Feb 7, 2011

- Messages

- 5,039

look here

Homemade R8 Collet Blocks - HomemadeTools.net

Homemade collet blocks intended to accommodate R8 collets. Fabricated from round and hex stock.

www.homemadetools.net